Automated Kappa Number System for Pulp and Paper Analysis

System Advantages

- Precise and accurate measurements – make better decisions and cut costs with improved confidence in test results

- Analyzes up to 17 samples in standard tall-form 300mL beakers

- Decrease laboratory chemicals – the kappa methodology cuts the volume of reagents required per test by as much as 6

- Easy to Use – This fully automated system has user-defined autorun buttons which make analysis simple and free of human error

- MANTECH’s robust hardware is completely controlled by the software

- All samples are maintained at a constant temperature

- Adaptable to other applications such as liquors (black, white and green), alkalinity, peroxide, etc.

MANTECH’s Kappa Number Analysis System fully automates the analysis of up to 17 pulp and paper samples. MANTECH understands that pulping, oxygen delignification and extraction processes require constant and reliable Kappa Number Tests in order to maintain good process control. The successful automation of the Kappa methodology allows Pulp and Paper laboratories to free up operator/technician time, reduce chemical costs, calibrate on-line automated Kappa analyzers and improve analytical confidence.

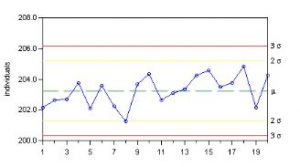

Sample Results

These real time quality control charts are generated using MANTECH’s PC-Titrate Software, which comes standard with every system.

The control chart shows the average results (green dashed line). It also shows the 2 & 3 sigma results. Statistically this refers to the results that are within 2 & 3 standard deviations of the average. They are an indication of accuracy. The 2 sigma indicates that the data has a 95% probability of being within the acceptable deviation, and 3 sigma indicates the data has a 99.7% probability of being within the acceptable deviation.