- How do I prepare liquid ATU from the reagent powder?

Dissolve one gram of 98% allylthiourea into 500 ml of DI water. This stock solution is good for 14 days, and must be refrigerated.

Dilute 10 ml of stock solution for every 100 ml of liquid inhibitor required for the number of samples to be set up each day. For example, if 250 mL of inhibitor is required, use 25 mL of stock solution.

The dilute solution must be prepared daily, as the solution is not stable.

Allylthiourea 98% – CAS# 109-57-9 – GFS Part # 5192

- What is the difference between membrane and optical DO probes?

MANTECH supports both membrane and optical DO probes as both are approved by SM 5210B.

Maintenance – The main benefit of optical over membrane is the maintenance aspect.

- Membrane probes are much more sensitive to storage conditions, operating practices, and the membranes need to be changed quite often.

- Optical sensor caps last a lot longer and storage is not as critical, though our systems do still store automatically regardless of probe type.

Stability Time

- Stability timing for each measurement is similar, can take a bit longer for optical vs membrane.

- Stability of the measurements over an entire run or between multiple runs is better with the optical.

For these reasons, MANTECH recommends the optical probe and ~90% of MANTECH customers use optical probes. Ultimately, it is your preference and MANTECH BOD systems support either probe.

- Is PC-BOD software compatible with Windows 10 or 11 OS?

As a result of major security updates Microsoft has implement, MANTECH cannot guarantee that PC-BOD will operate if updates in Windows 10 or 11 Pro operating systems. PC-BOD can operate in virtual mode however, this leaves the analyzer vulnerable to viruses (leading to corrupted databases) and could impact the software when Windows updates are performed. Here is some more information about everything you need to know before updating to Windows 10…read more. In 2021, MANTECH introduced a line of all new hardware and BOD Pro software designed for Windows 10 and 11 Pro OS – meaning that all security and OS updates can run concurrently.

There are a few different options to move forward:

- Install PC-Titrate on Windows 10 computer (no guarantee).

- Replace the entire system (all new hardware and software) with a trade-in discount for your existing system.

To discuss your options, please contact our team here.

- How is DI water connected to MANTECH Analyzers for rinsing?

MANTECH Analyzers utilize peristaltic pumps for rinsing that can pull DI water either from a static reservoir or container located near the analyzer, or from a pressurized line connected directly to the rinse pump inlet.

IMPORTANT NOTE: If drawing DI water from a pressurized line, it is important that the pressure in the line does not exceed 20 psi. A pressure regulator valve can be installed between the line hookup and the rinse pump to reduce pressure below this limit.

- What is the Conductivity (uS/cm) of Dilution Water?

Typically, dilution water is about 130-135 uS/cm. If using seeded dilution water, expect around 100 uS/cm.

Note: The conductivity threshold of MANTECH’s level sensor is 50 uS/cm. Dilution water made must have a conductivity value greater than 50 uS/cm. Deionized water will not trigger the level sensor.

- What are the Specifications for Ethernet and USB Hubs?

See below for hub specifications:

Specification Ethernet Hub USB Hub Ports 5 10 Power Input (AC) 100-240V 100-240V USB N/A USB 2.0 Driver Required No No Note: All hubs must be directly connected to power for all system installations. MANTECH does not recommend hubs acquiring power solely from the USB connection of the computer.

- Are BOD results affected by atmospheric pressure changes?

Generally speaking, dissolved oxygen readings are dependent on atmospheric pressure. This is because the density of water changes with pressure, and this in turn affects the mg/L of dissolved oxygen. Here is a resource describing the “why” behind this. It is also dependent on temperature for similar reasons.

The YSI meter does compensate for changes in atmospheric pressure. Here is a document explaining this. The document also provides advice for troubleshooting when challenges are occurring in BOD testing. One important aspect is to make sure you are calibrating the probe before each day of testing.

- What are QC racks and what capacities are available?

Available as an optional add-on, MANTECH offers a separate fixed rack located in front of the rinse station for placing calibration solution, storage solution(s), and QC checks instead of limiting the sample rack capacity. Capacities range based on autosampler and tube/cup size.

MT Series QC Rack Options

Part Numbers # of Positions Tube/Cup Size Autosampler Model PC-AM400-QC-50-24 24 50mL All AM400 Models PC-AM400-QC-50-36 36 50mL AM402, AM403, AM404, AM405 PC-AM400-QC-50-48 48 50mL AM403, AM404, AM405 PC-AM400-QC-120-9 9 120mL All AM400 Models PC-AM400-QC-120-18 18 120mL AM402, AM403, AM404, AM405 PC-AM400-QC-120-27 27 120mL AM403, AM404, AM405 PC-AM400-QC-125-7 7 125mL All AM400 Models PC-AM400-QC-125-14 14 125mL AM402, AM403, AM404, AM405 PC-AM400-QC-125-21 21 125mL AM403, AM404, AM405 BOD QC Rack Options

Part Numbers # of Positions Tube/Cup Size Autosampler Model PB-10265 3 300mL All AM400 Models - My DO meter isn’t communicating to BOD Pro. Is there a way to reset it?

First, confirm the correct COM port is selected. If this does not work, you will need to the reset the meter’s firmware. For step-by-step instructions, view PDF here.

- I'm having troubles connecting my MiniHub. Is there a way to reset it to factory settings?

Yes! Follow our short tutorial on resetting your MiniHub to factory settings if it does not connect to the IP address of 192.168.1.10

Follow our updated technical bulletin here.

- What are the Dimensions and Space Requirements for MANTECH Systems?

The measurements listed below are based on standard MT-Series systems. Measurements and pictures include the MANTECH System Organizer (MSO), where applicable. System controllers and computer monitors are not included in the dimensions described below.

AM400 Only Configuration (No MSO):

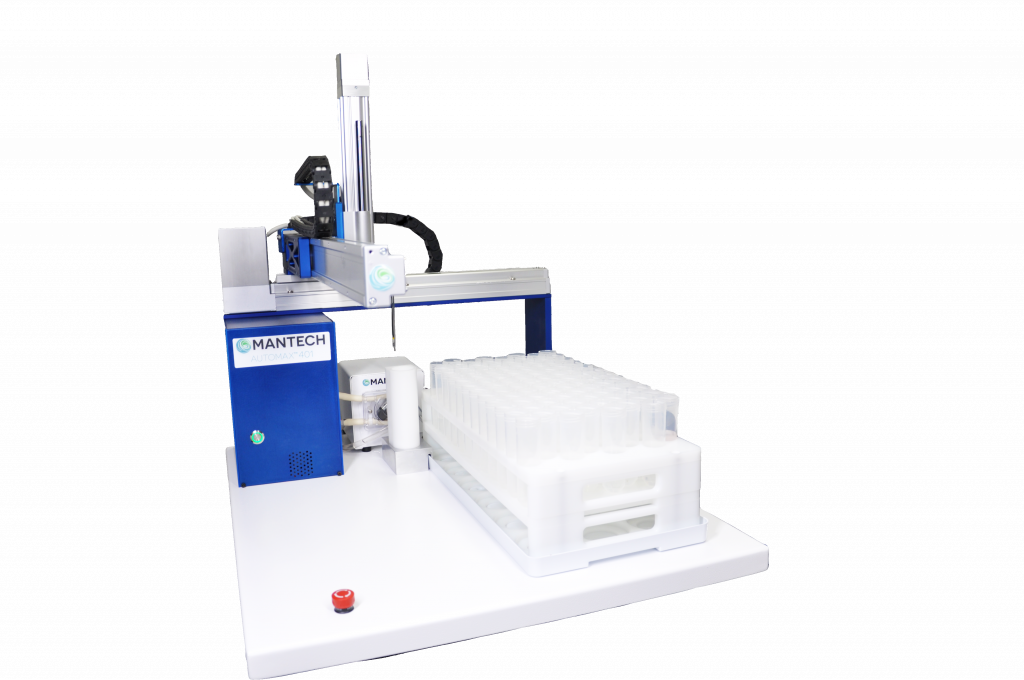

AutoMax401 AutoMax402 AutoMax403 AutoMax404 AutoMax405 W 24” / 62cm 36” / 92cm 48″ / 122cm 60″ / 152cm 72” / 182cm D 29” / 74cm 29” / 74cm 29” / 74cm 29” / 74cm 29” / 74cm H 29.5” / 76cm 29.5” / 76cm 29.5” / 76cm 29.5” / 76cm 29.5” / 76cm Example MANTECH system with AM400 Only Configuration

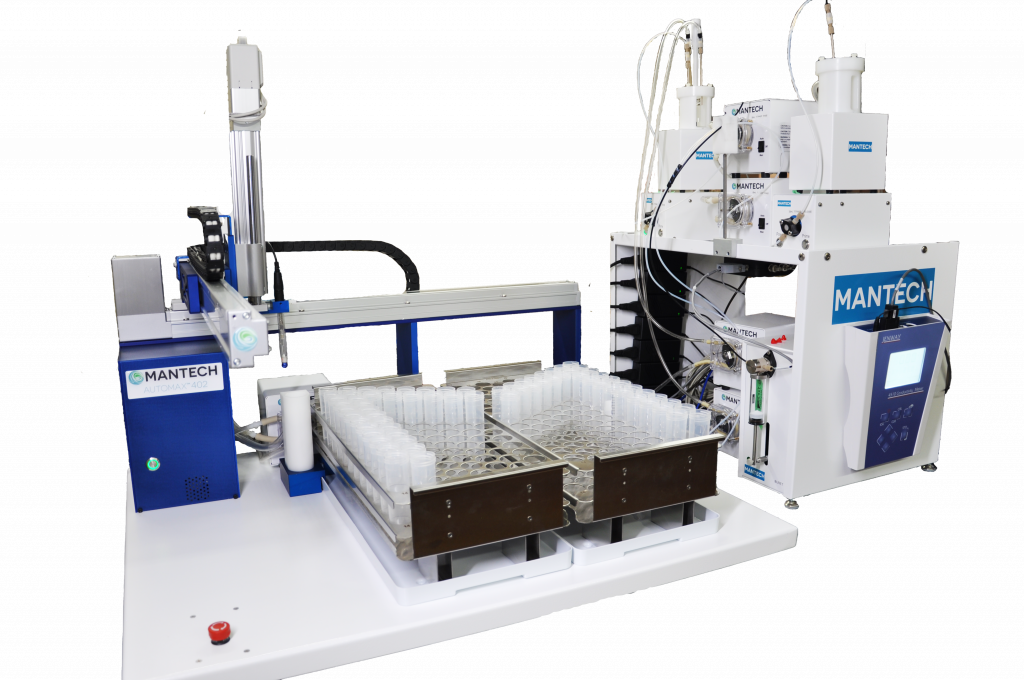

Tall Side MSO Configuration (Recommended Configuration):

AutoMax401 AutoMax402 AutoMax403 AutoMax404 AutoMax405 W 42” / 108cm 54” / 138cm 66” / 168cm 78” / 198cm 90” / 228cm D 29” / 74cm 29” / 74cm 29” / 74cm 29” / 74cm 29” / 74cm H 40” / 102cm 40” / 102cm 40” / 102cm 40” / 102cm 40” / 102cm Example MANTECH system with tall side MSO

Short Side MSO Configuration:

AutoMax401 AutoMax402 AutoMax403 AutoMax404 AutoMax405 W 42” / 108cm 54” / 138cm 66” / 168cm 78” / 198cm 90” / 228cm D 29” / 74cm 29” / 74cm 29” / 74cm 29” / 74cm 29” / 74cm H 29.5” / 76cm 29.5” / 76cm 29.5” / 76cm 29.5” / 76cm 29.5” / 76cm Example MANTECH system with short side MSO

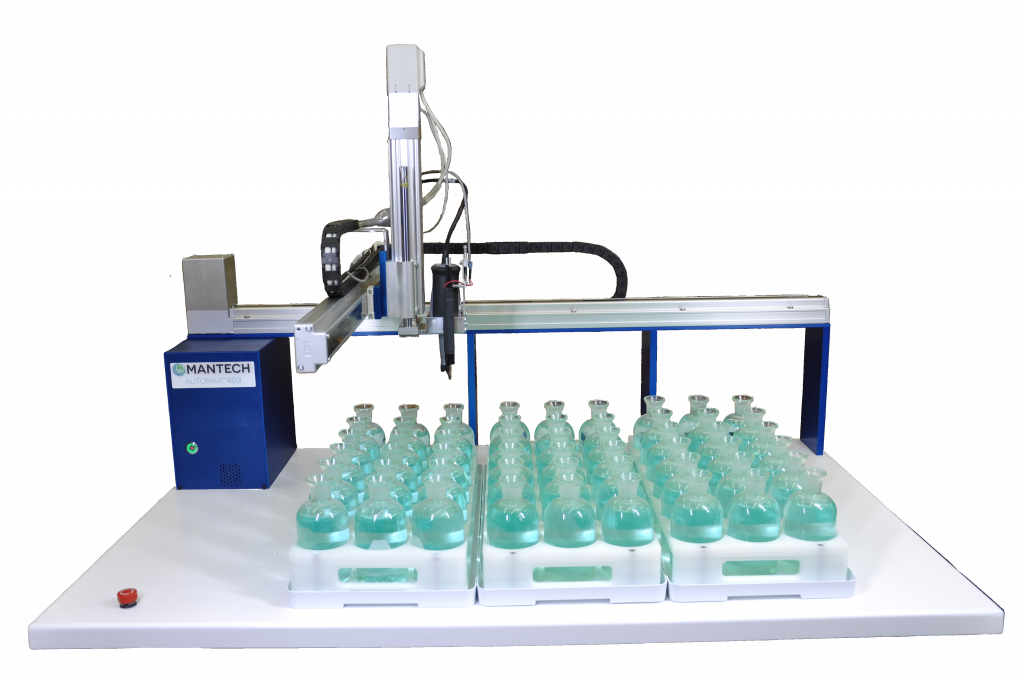

AM400 Series BOD Systems (No MSO):

AutoMax401 AutoMax402 AutoMax403 AutoMax404 AutoMax405 W 24” / 62cm 36” / 92cm 48” / 122cm 60” / 152cm 72” / 182cm D 29” / 74cm 29” / 74cm 29” / 74cm 29” / 74cm 29” / 74cm H 29.5” / 76cm 29.5” / 76cm 29.5” / 76cm 29.5” / 76cm 29.5” / 76cm Example MANTECH BOD system with no MSO (Note: modules are to be placed on sampler bed or next to the sampler)

- Do you offer barcoding options?

Yes, we do offer barcoding options. Barcoded labels will help you quickly identify results. Barcoded options are available and additional hardware is required.

- Are your stirrers manual or automatic?

BOD Pro™ Software detects the optimal time to turn on the stirrer while taking DO readings. This feature improves operational efforts for analysts and streamlining your runs.

- What service and support options are available?

MANTECH offers options for on-site or remote assistance. With the customer’s permission, a MANTECH representative can remotely control operations, answers questions, resolve challenges and assist with any other requests. MANTECH offers on-site support with one of our Technical Representatives within 72 hours across Canada and the U.S. Our team of Technical Representatives will assist in installation, repairs, and preventative maintenance of your systems. Find your nearest Technical Representative here. For on-site services outside of Canada and the U.S., please contact your distributor here.

- What is BOD Pro software?

Following months of BETA testing, in early 2022, MANTECH has released new software called BOD Pro. BOD Pro is a lab automation software that is entailed to operate our automated and manual BOD systems with plenty of features that analysts desire.

- What DO meter is required for BOD Pro?

BOD Pro has been designed to integrate YSI MultiLab DO meters. MANTECH offers single, dual or triple probe options to cut busy laboratory’s run times to a fraction of the time! BOD Pro supports YSI MultiLab 4010-W series including:

- YSI MultiLab 4010-1W

- YSI MultiLab 4010-2W

- YSI MultiLab 4010-3W

A manual data entry option allows customers can use alternative DO meters.

Note: BOD Pro Software does not support the YSI MultiLab 4010-1, 4010-2, and 4010-3 models.

- Is BOD Pro compatible with my LIMS system?

Yes. BOD Pro™ Software is agnostic, and our CSV import/export functionality is easy-to-use and flexible with all LIMS systems.

- What are the computer specifications to operate BOD Pro?

BOD Pro software requires a computer with Windows 10/11 Pro OS with minimum 4GB RAM. View PDF for Minimum Computer Requirements here.

- Will BOD Pro operate with the hardware I currently have?

BOD Pro has been designed for MANTECH’s latest hardware releases. Learn more about our new hardware here.

Hardware trade-in offers are available for existing PC-BOD customers.

- What are shortcuts?

Shortcuts are customizable buttons that users can create from pre-saved templates generated on Run Configuration table. Shortcuts can have its own unique image and be organized by custom headers.

- What BOD Incubator Does MANTECH Recommend?

The 5-day Biochemical Oxygen Demand (BOD5) test requires that samples be incubated for a period of 5 days between the initial reading of dissolved oxygen, and the final reading. The environment the samples are incubated in must be strictly controlled at 20°C for the entirety of the 5 days, and the best option for establishing this environment is an incubator. There are a wide variety of incubators available in the market with different dimensions and volumes, accommodating more or less samples depending on a laboratory’s requirements.

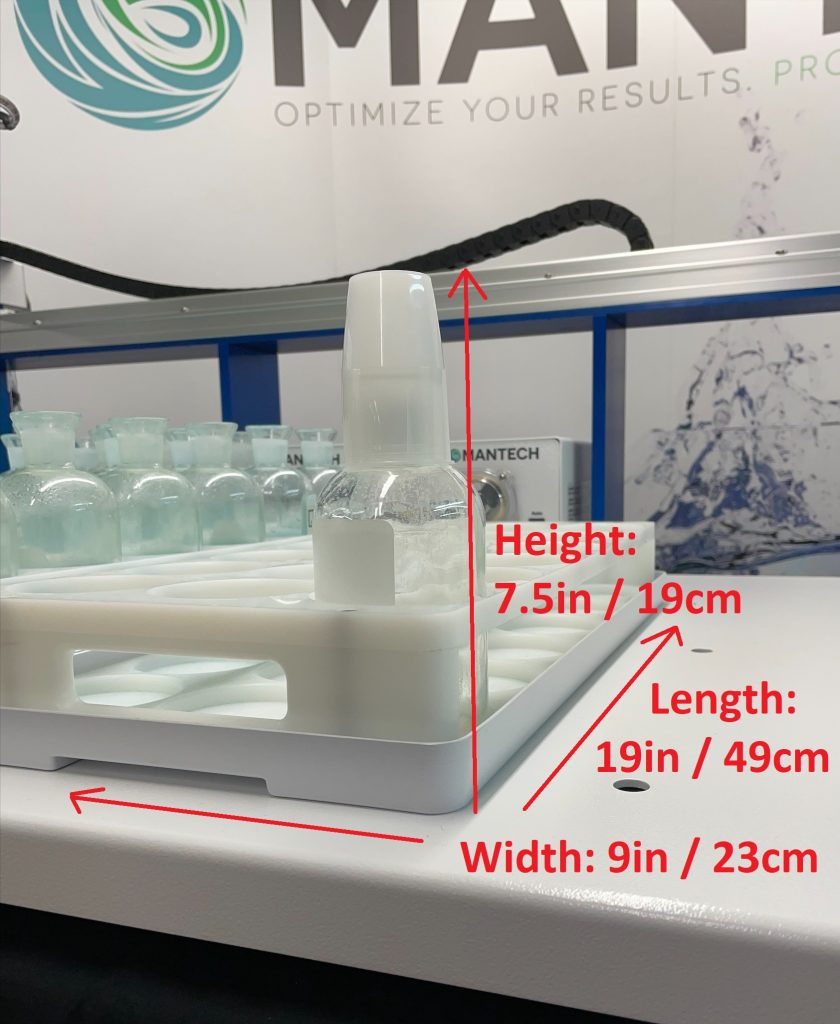

MANTECH’s BOD Pro analyzer automates the preparation and analysis of sets of samples for this BOD5 test using a multi-position autosampler along with pumps and other components. MANTECH’s AM400 autosamplers all accommodate 12- position or 18-position racks which the operator places the sample bottles into, then starts the run. After the analysis is complete, the operator applies stoppers and overcaps to the bottles according to the Standard Methods, and the sample bottles are placed in the incubator. For the BOD Pro systems, it is greatly beneficial to keep the bottles in position on the racks and place the full racks in the incubator, to save time and effort for the operators.

The dimensions of an 18-position BOD rack with bottles, stoppers and overcaps applied are provided below:

L – 19in/49cm

W – 9in/23cm

H – 7.5in/19cm

The dimensions of a 12-position BOD rack with bottles, stoppers and overcaps applied are provided below:

L – 19in/49cm

W – 6in/15cm

H – 7.5in/19cm

When sourcing an incubator for your lab’s BOD analysis, you will want to consider the total number of bottles expected to be analyzed every week, as well as the number of racks those bottles will occupy. For example, if your lab analyzes 200 BOD bottles every week, this would correspond to 12 18-position racks, with the last rack only being partially filled but still taking up the space of a full rack in the incubator.

Some examples of recommended incubator models and their bottle capacities both including racks, and not including racks, are provided below:

Brand Model # Description Capacity with 18-position Racks Capacity with 12-position Racks Capacity w/o Racks Link Fisher Scientific S50441A Economy Standard Incubator, 19.8 L, Aluminum x x 12 https://www.fishersci.ca/ Fisherbrand 15-015-2633 Microbiological Incubator, 60 L, Stainless Steel x x 75 https://www.fishersci.ca/ Fisherbrand 15-015-2634 Microbiological Incubator, 117 L, Stainless Steel x x 108 https://www.fishersci.ca/ Fisherbrand 15-015-2645 Microbiological Incubator, 180 L, Stainless Steel 108 108 144 https://www.fishersci.ca/ Fisherbrand 15-103-1569 Isotemp™ 400 Refrigerated Incubator, 381 L, Stainless Steel 252 252 343 https://www.fishersci.ca/ Fisherbrand 3720A Isotemp™ BOD Refrigerated Incubator, 566 L, Porcelain Steel 288 384 441 https://www.fishersci.ca/ Thermo Scientific 13-262-340 Forma™ Environmental Chamber Model 3920, 821.2 L, Stainless Steel 432 576 792 https://www.fishersci.ca/ - What is the flow rate of the IntelliPump?

The MANTECH IntelliPump is a variable speed intelligent pump that is controlled in speed and direction by the MANTECH Pro software. The pump is set at a specific speed (1-100) and either 1/4″ or 1/8″ diameter tubing is used to achieve desired flow rates for various applications. The pump can then be calibrated by measuring liquid dispensed over a set period of time, and entering the value into the Hardware Configuration window of the software.

Pumps are assigned a default estimated flow rate based on the speed setting and tubing size, and this flow rate is used unless the end user decides to run a pump calibration. The estimated flow rates for various speed and tubing settings are provided below:

Tubing Diameter (inches) Speed Setting (%) Flow Rate (mL/min) 1/8” 6 (min) 1.9 10 17.88 20 56.22 30 92.27 40 126.02 50 157.47 60 186.63 70 213.49 80 239.05 90 260.32 98 (max) 276.48 1/4” 3 (min) 2.79 10 61.82 20 146.15 30 230.48 40 314.81 50 399.14 60 483.47 70 567.80 80 652.13 90 736.46 99 (max) 812.36 - What is the weight and dimensions for AM400 autosamplers?

Autosampler Model Dimensions in Inches Dimensions in Centimeters Crate ONLY (in lbs) Crate ONLY (in kg) Weight Estimates with System & Accessories (in lbs)* Weight Estimates with System & Accessories (in kg)* 401 24 x 33 x 29 62 x 85 x 74 75 34 200 91 402 36 x 33 x 29 91 x 85 x 74 91 41 250 113 403 47 x 33 x 29 122 x 85 x 74 107 49 275 125 404 59 x 33 x 29 151 x 85 x 74 118 54 300 136 405 71 x 33 x 29 183 x 85 x 74 130 59 325 148 *Actual weight may vary by actual system and accessories.

- How do you calculate seed correction and BOD?

To learn how to calculate Seed Correction and BOD, please refer to this document. In BOD Pro, two separate values for Seed Correction Factor are stored along with the Run; one is referred to as BODSeedCorrection, and the other CBODSeedCorrection. The way we calculated BODSeedCorrection in BOD Pro is as follows:

- Dividing the depletion of each BOD Seed bottle by its own volume (the seed volume), the resulting quantity is referred to as DepletionPerMLSeed

- and then we average the DepletionPerMLSeed over all the BOD Seed bottles.

CBOD Seed Correction was calculated by doing the same on CBOD Seed bottles. The software allows for only one Seed ID to be included in the Run. There can be any number of BOD or CBOD Seed bottles within that Seed ID group.

- What does high BOD indicate?

BOD indicates the amount of putrescible organic matter present in water. Therefore, a low BOD is an indicator of good quality water, while a high BOD indicates polluted water. Dissolved oxygen (DO) is consumed by bacteria when large amounts of organic matter from sewage or other discharges are present in the water.

- What is the BOD of raw sewage?

BOD can also be defined as the amount of oxygen required by the micro-organisms in the stabilization of organic matter. The results are generally expressed as the amount of oxygen taken by one litre sample (diluted with aerated water) when incubated at 20 degree for five days. BOD of raw sewage is 300-600 mg/litre.

- What is biochemical oxygen demand?

Biochemical Oxygen Demand (BOD), also often referred to as biological oxygen demand, is a test performed to measure the potential of wastewater and other waters to deplete the oxygen level of receiving waters. In other words, the BOD test is performed to determine what effect dirty water, containing bacteria and organic materials, will have on animal and plant life when released into a stream or lake. Learn more here.

- What is the measuring range for Dissolved Oxygen on MANTECH systems?

MANTECH systems utilize one of two dissolved oxygen probes from YSI for automated dissolved oxygen determination. The measuring ranges of both probes are listed below, along with a link to the complete specification sheets.

YSI FDO 4410 IDS Sensor

- Dissolved Oxygen Range: 0 to 20 mg/L

- Air Saturation Range: 0 to 200%

- Temperature Measurement Range: 0 to 50°C

- Technical Specifications

YSI ProOBOD Sensor

- Dissolved Oxygen Range: 0 to 50 mg/L

- Air Saturation Range: 0 to 500%

- Temperature Measurement Range: Ambient 10 to 40°C; Compensation -5 to 50°C

- Technical Specifications

- How does the PeCOD method compare to BOD, TOC, and conventional COD?

There are several common methods to test wastewater and drinking water for organic pollutants, natural and chemical. Chemical Oxygen Demand (COD), Biochemical Oxygen Demand (BOD) and, Total Organic Carbon (TOC) compromise the three main methods of testing water samples. BOD and COD methods differ from TOC because they measure the amount of oxygen that is depleted by organic species in water. Moreover, TOC is a measure of all carbon (both organic and inorganic), rather than the oxygen that is reduced by these species. As written by a TOC manufacturer, “TOC on its own sheds no light on the oxidizability of the measured carbon or the amount of oxygen needed for its biodegradation.” Specific to COD, it measures the reactive fraction of the TOC. This is also known as oxidizability in the European Union.

View the full article: Comparison of COD, BOD and TOC Methods for organics, which summarizes the advantages and disadvantages of the COD, BOD and TOC methods, and compares them to the PeCOD method.

- How do I retrieve calibration records from my YSI 4010 MultiLab IDS meter?

The YSI 4010 MultiLab IDS meter will store the records for the last 10 calibrations performed on the meter. The instructions for retrieving these calibrations can be found on Technical Bulletin 2021 – 010.

- What does high BOD indicate?

BOD indicates the amount of putrescible organic matter present in water. Therefore, a low BOD is an indicator of good quality water, while a high BOD indicates polluted water. Dissolved oxygen (DO) is consumed by bacteria when large amounts of organic matter from sewage or other discharges are present in the water.

- What is the BOD of raw sewage?

BOD can also be defined as the amount of oxygen required by the micro-organisms in the stabilization of organic matter. The results are generally expressed as the amount of oxygen taken by one litre sample (diluted with aerated water) when incubated at 20 degree for five days. BOD of raw sewage is 300-600 mg/litre.

- What is the COD to BOD ratio in domestic sewage influent?

BMS have recorded average ratios of 2-3 mg/l COD to 1 mg/l BOD over its 30 years of business. Influent COD in normal domestic sewage is therefore generally 600 – 900 mg/l and it is then treated to at least 30 -100 mg/l before discharge to minimize pollution potential.

- How does PC-BOD calculate BOD when samples have failed BOD Method criteria?

- If all samples fail the final DO rule, the software will report the value for the sample with the highest dilution (lowest sample volume) and display a greater than (>) symbol.

- If all samples in a set fail the depletion rule and the BOD of the bottle with the lowest dilution (highest sample volume) is greater than the minimum detection, the software will report the value for the sample with the lowest dilution (highest sample volume) and display a less than (<) symbol.

- A less than symbol (<) will appear when all samples in a set have a depletion of less than that specified in the BOD Method. If the BOD of the bottle with the lowest dilution (highest sample volume) is less than the minimum detection for a given sample condition, the average will be displayed as follows:

- Diluted samples with no seed added < 2 mg/L

- Diluted samples with seed added < 1 mg/L

- Undiluted samples with no seed added < 0.1 mg/L

- Undiluted sampled with seed added < 0.0 mg/L

- How long does it take to measure initials and finals on a MANTECH AM300 series multi-rack system?

The length of time to measure initials and finals on a MANTECH AM300 series multi-rack system varies depending on the method of sample preparation, sampler size, and probe style. For an example of a typical MANTECH BOD system click here. For an individualized estimate contact us at [email protected].

- What information is required to automate biochemical oxygen demand?

Automating the biochemical oxygen demand (BOD) test can greatly increase the efficiency and production capacity of a laboratory. To automate this analysis, the following information is required:

- How many bottles on average do you set up for an initials batch?

- For example, this accounts for all samples and all dilutions per sample, plus blanks, GGA’s, etc.

- How often do you set up Initials?

- For example, many laboratories set up Initials on Wednesday, Thursday, and Friday then Finals on Monday, Tuesday, and Wednesday since the laboratory is closed on weekends.

- What is the maximum number of bottles in your incubator at any one time?

- Do you analyze BOD, cBOD, or both?

- What is the source of most samples that you are analyzing

- For example, municipal WW, industrial WW, surface water, etc.

- What percentage of samples do you know the approximate BOD of before analysis?

- Who are the clients or users of the BOD information?

- For example, industrial pre-treatment, WWTP effluent compliance, WWTP engineers, etc.

- How many bottles on average do you set up for an initials batch?

- What are the dimensions of MANTECH BOD Autosampler Racks?

Part Number Rack Size Autosampler Model Bottle Style Depth Width Rack Height Rack Height w/ Bottles PB-10246 18 x 300mL AM400 & AM300 Series Glass 487.68 mm

19.2 inches

236.22 mm

9.03 inches

63.5 mm

2.5 inches

2.69 mm + bottle height

0.106 inches + bottle height

PB-10247 18 x 300mL AM400 & AM300 Series Plastic 487.68 mm 19.2 inches

236.22 mm 9.03 inches

63.5 mm 2.5 inches

2.69 mm + bottle height

0.106 inches + bottle height

PB-10248 12 x 300mL AM400 Series Glass 487.68 mm

19.2 inches

153.42 mm

6.04 inches

63.5 mm

2.5 inches

2.69 mm + bottle height

0.106 inches + bottle height

PB-10255 12 x 300mL AM400 & AM300 Series Plastic 487.68 mm 19.2 inches

153.42 mm 6.04 inches

63.5 mm 2.5 inches

2.69 mm + bottle height

0.106 inches + bottle height

PB-10293 12 x 300mL AM430 Series Glass 320.04 mm 12.6 inches

229.36 mm 9.03 inches

63.5 mm 2.5 inches

2.69 mm + bottle height

0.106 inches + bottle height

PB-10295 12 x 300mL AM430 Series Plastic 320.04 mm 12.6 inches

229.36 mm 9.03 inches

63.5 mm 2.5 inches

2.69 mm + bottle height

0.106 inches + bottle height

PB-10138 11 x 300mL AM73 Plastic 337 mm

13.25 inches

234 mm

9.19 inches

88 mm

3.13 inches

8 mm + bottle height

0.313 inches + bottle height

PB-10139 11 x 300mL AM73 Glass 337 mm

13.25 inches

234 mm

9.19 inches

88 mm

3.13 inches

8 mm + bottle height

0.313 inches + bottle height

PB-10162 23 x 300mL AM122 Glass 488 mm

19 inches

307 mm

12.06 inches

71 mm

3.81 inches

9.5 mm + bottle height

0.375 inches + bottle height

PB-10163 23 x 300mL AM122 Plastic 488 mm

19 inches

307 mm

12.06 inches

71 mm

3.81 inches

9.5 mm + bottle height

0.375 inches + bottle height

PB-10060 (discontinued) 24 x 300mL Glass/Plastic 485 mm

18.82 inches

315 mm

12.38 inches

193 mm

7.60 inches

5 mm + bottle height

0.188 inches + bottle height

PB-10133 (discontinued) 24 x 300mL Glass/Plastic 485 mm

18.82 inches

315 mm

12.38 inches

131 mm

5.125 inches

5 mm + bottle height

0.188 inches + bottle height

- How do I configure the YSI 4010 MultiLab IDS meter for PC-BOD?

To use the YSI 4010 MultiLab IDS meter with PC-BOD, the appropriate driver, computer settings, and software settings must be applied. Download the Technical Bulletin for more details.

- Why does the barometer reading on my YSI 4010 MultiLab IDS meter not match the reading documented by my local weather service?

The YSI MultiLab IDS meter outputs a true barometric pressure reading of its location, which is dependent on elevation above sea level.

Local weather services typically use a corrected barometric pressure reading, which corrects the reading to sea level.

To approximate the true barometric pressure reading from a corrected barometric pressure reading, use the following equation:

True barometric pressure [mmHg] = Corrected barometric pressure [mmHg] – (0.025 * local altitude [feet] )

- Can I calibrate the internal barometer on my meter?

The internal barometer on the YSI MultiLab IDS meter is calibrated upon manufacturing and is designed to last the lifespan of the barometer sensor. The sensor is very stable and can last many years. Standard Methods does not specify a requirement for an adjustable barometer for dissolved oxygen measurements or biological oxygen demand testing.

- How do I calibrate my DO probe with the YSI 4010 MultiLab IDS Meter?

Unless otherwise specified in company or site-specific procedures, specifications, and regulations, a water vapor-air saturated calibration should be sufficient for probe calibration. For full calibration procedures, please refer to the following pdf.

- How do I set the sensor cap coefficients in my YSI 4010 MultiLab IDS meter?

Follow the step-by-step instructions in the pdf.

- How do I set the date and time in my YSI 4010 MultiLab IDS Meter?

Follow the step-by-step instructions in the pdf.

- What is the difference between BOD and cBOD?

Biochemical oxygen demand (BOD) is a way to assess the amount of oxygen required for aerobic microorganisms to decompose the organic material in a sample of water over a specific time frame. It is the oxygen uptake demand of a source of water. Carbonaceous biochemical oxygen demand (CBOD) is the same method as BOD, but the nitrifying bacteria in the sample are inhibited. Nitrifying bacteria consume nitrogenous materials (compounds with reduced forms of nitrogen) and add to the oxygen demand of the wastewater. Nitrogenous materials are often seen as interference because the purpose of the BOD test is to measure carbonaceous material.

Automated Biochemical Oxygen Demand (BOD) Analysis Solutions

MANTECH has a variety of biochemical oxygen demand (BOD) systems to best suit the needs of your laboratory. Whether you need manual or automated, big or small, simple or complex, MANTECH can create the ideal BOD solution for your laboratory. MANTECH’s Automated BOD analysis systems are robust, come with easy to use software, and provide accurate results that stand the test of time.

Download the BOD method abstract.

NEW: BOD Pro Software Package for Manual or Automated Solutions

Automated BOD with 10 minute BOD estimator Packages – ALL in ONE

BOD Analyzer Benefits

-

Automates the 5-day and 7-day BOD and CBOD standard analysis methods. Conforms to ASTM Standard Methods 5210B 23rd and 24th Editions, ISO EN 5815, ISO EN 1899-1, -2

-

Eliminates potential for human error by automating up to five pumps for reagent addition

-

Automated DO probe calibrations and calibration checks either on rack or at a separate side position, with automated recalibration and re-reading of previous samples when required

-

Customizable user interface to simplify operation

-

Easily manage and prioritize samples during analysis

-

Quickly identify results with barcoded labels

BOD Analyzer Models

MANTECH systems are highly configurable to meet your current needs and can be upgraded with any of the following features to grow with your laboratory’s demands. Customers are able to pick from a variety of any of the following off-the-shelf options.

MANTECH’s next generation autosamplers are quieter, faster and more accurate. Featuring sealed, self-lubricating axes for no maintenance and a single anchor point to eliminate binding. Capacities range from 18 – 108 positions of standard 300mL bottles.

AM401 |

AM402 |

AM403 |

AM404 |

AM405 |

|

|---|---|---|---|---|---|

12 Place Rack |

N/A |

36 (3 racks) |

60 (5 racks) |

84 (7 racks) |

108 (9 racks) |

18 Place Rack |

18 (1 rack) |

36 (2 racks) |

54 (3 racks) |

72 (4 racks) |

90 (5 racks) |

Dimensions (w x h x d)AM400 only vary in width |

24.2 x 33.5 x 29.2” 62 x 85 x 74 cm |

36 x 33.5 x 29.2” 91 x 85 x 74 cm |

47.5 x 33.5 x 29.2” 122 x 85 x 74 cm |

59.4 x 33.5 x 29.2” 151 x 85 x 74 cm |

71 x 33.5 x 29.2” 183 x 85 x 74 cm |

MANTECH systems can automate sample preparation, DO reading and rinsing in 90 secs/bottle (depending on stability settings). Customers have the choice to automate the addition of dilution water, seed and/or inhibitor (ATU) utilizing:

Featuring bi-directional communication, BOD Pro software controls the flow rate and direction of the peristaltic pump and can be used for dilution water and inhibitor (ATU) addition. Calibrate via the software for +/- 1% precision.

Ceramic piston metering pumps deliver seed with +/- 0.2% precision.

MANTECH also offers our market-leading 100,000 step resolution syringe-based pump for inhibitor (ATU) addition.

As per SM 5210B 23rd edition, if pH is not between 6.0 – 8.0, then sample must be adjusted to pH between 6.5 – 7.5. This system automates the pH measurement and adjustment of the sample while recording all data.

Single sample station that includes:

- pH probe

- Probe holder and stand

- Software to perform analysis and record data

MT4 for pH Measurement & Adjustment

Single sample station that includes:

- pH probe

- Probe holder and stand

- Software to perform analysis and record data

- Peristaltic pumps to deliver acid or base (option for 1 or 2 depending on the procedure needed to adjust within desired range)

MT30 for Automated pH Measurement & Adjustment

Multi-sample system that includes:

- pH probe

- Autosampler with dynamic flowing rinse station

- Software to perform analysis and record data

- Peristaltic pumps to deliver acid or base (option for 1 or 2 depending on the procedure needed to adjust within desired range)

- Available custom racks for sample bottles

In addition to automating sample preparation and DO readings, MANTECH’s BOD systems can automate sample transfer to dilution bottles. This complete package includes:

- x2 Autosamplers – 1 for sample bottles and 1 for dilution bottles

- Allows for flexible set up to accommodate your limited bench space (i.e. side-to-side, back-to-back, perpendicular)

- The second autosampler can be utilized for additional analyses during down time (i.e. pH, alkalinity, EC, hot acidity, etc.)

- Thorough rinsing and cleaning procedures

- No-clog pipetting pump

ONLY $1,990 USD!

MANTECH offers a low investment and small footprint solution for manual DO readings for BOD5 analysis. Coupled with the NEW MANTECH designed BOD Pro software, this system is ideal for smaller laboratories who analyze a few samples per month.

System Features:

- Custom shortcut buttons

- Incubation period tracking

- Performs calculations

- Use your existing DO meter

- LIMS reporting