One of the most common reasons for Turbidity QCs failing is due to DI water that is not degassed being used for blanks and standards preparation.

Any dilutions used to prepare turbidity standards, as well as blanks, must use degassed DI water. This is especially important for accurate low-end turbidity analysis, as there is often a positive bias due to bubbles introduced into the DI water solution when it is being produced/dispensed. This effect becomes more noticeable with lower NTU readings, and can cause challenges with performing an accurate calibration. To degas DI water, it must be dispensed into a very clean bottle or container, and left to sit for ~24h. You will see bubbles form on the side of the container as the water degasses. After degassing, it is ready to use for blanks and standards preparation.

When your turbidity QCs are failing, it is best to do the following:

- Ensure you are using Degassed DI water

- If you do not have this, prepare by leaving DI water to sit for 24h in a very clean bottle or container

- Repeat the QCs with a freshly-prepared standard

- If still failing, perform a new multi-point calibration, followed by x3 blanks then the same QC standards, all with fresh solutions

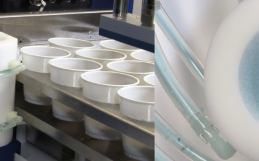

- If still failing the above, remove the flow cell and clean it, and also perform a new meter calibration with the set of sealed cuvette standards

- Then, reinstall the flow cell and perform a new free calibration, then a new multi-point calibration, followed by x3 blanks then the same QC standards, all with fresh solutions