Petrochemical Industry

PeCOD® Case Study #01

Optimizing process efficiency for petrochemical wastewater monitoring is a key step in achieving sustainable energy. Care must be taken to properly monitor and treat wastewater generated from petroleum refineries to ensure contaminants are not released into the surrounding environment. Fast, safe, and reliable detection technology is therefore highly sought after and enables plant operators to make informed decisions regarding wastewater organic load and discharge limits.

Chemical oxygen demand (COD) is a common parameter used for assessing organic contamination of wastewater. The following case study describes the application of the PeCOD® COD Analyzer for use in the oil and gas industry with widely varying samples. The intention of this study was to evaluate a variety of products in their ability to treat wastewater. The PeCOD® method for COD analysis is well suited for use in the petrochemical industry as it fulfills the need for both a rapid and environmentally friendly monitoring tool, providing real-time results important for process monitoring and control. In addition, rapid COD monitoring offers the operational feedback necessary for optimizing production practices and cleaning processes, often leading to a reduction in raw material consumption and discharge costs. The sample matrix discussed below consists of petrochemical effluent wastewater at a neutral pH, free from large, solid particulates. Samples were mixed in a 1:1 ratio with GREEN range PeCOD® electrolyte solution. Soluble COD was analyzed by the PeCOD® COD method and compared with dichromate COD (CODCr) results. Samples prepared for dichromate COD analysis were unfiltered and represent total COD values.

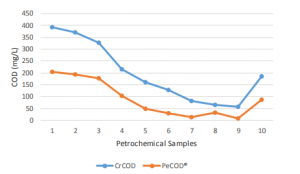

Figure 1: Trend chart for PeCOD® COD Analyzer results and Dichromate COD (CrCOD) results for 10 petrochemical effluent wastewater samples. A similar pattern is observed for each trend line.

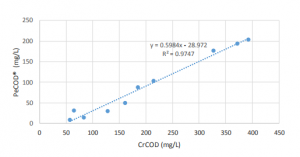

Figure 2: A linear regression of PeCOD® COD Analyzer results vs Dichromate COD (CrCOD) results. A strong correlation is observed shown by an R2 value of 0.97.

The preliminary objective of this study was to determine if a correlation exists between PeCOD® COD and the traditional CODCr method for waste streams in a specific petrochemical plant. As made apparent by Figure 1, the PeCOD® COD Analyzer consistently reports a COD value lower than reported by CODCr for each of the 10 petrochemical samples. The PeCOD® analyzer uses nanotechnology to measure soluble COD where the CODCr method reports total COD. The strong correlation between PeCOD® COD and dichromate COD (R2 = 0.97) shown in Figure 2 indicates that although the PeCOD® COD results tend to read lower, they are consistent and therefore predicable, making it a useful tool for measuring COD in the petrochemical industry.

The PeCOD® method provides consistent results faster than the dichromate method, offering plant operators continuous insight into organic load and allowing them to monitor discharge levels more efficiently. Another significant advantage of this investment are the health and safety improvements for company personnel through the elimination of dichromate, mercury, and concentrated acid required for the CODCr test. The PeCOD® COD Analyzer requires a simple, environmentally friendly electrolyte solution and calibrant to run. Additionally, consumable requirements are low and affordable, generating accurate and precise results on a continuous basis.

Author: Katelyn Wanka, B.Sc., M.BINF., Quality Control and Research Chemist at MANTECH

Download the full PDF here.