On-Site COD Real Time Measurement:

Ontario Food and Beverage Facilities – Pilot Project

MANTECH’s PeCOD® unit, installed in three food and beverage facilities to explore the feasibility of real time monitoring of Chemical Oxygen Demand (COD).

Potential benefits of real time COD measurement for the food and beverage sector:

- Real time data on wastewater discharge

- Quick notification when limits are exceeded

- Wastewater strength can be linked to operations

- Processes can be optimized to reduce wastewater composition

“The majority of small to medium-sized food and beverage processors do not have their own reliable data to properly characterize the composition of their wastewater.”

“Without (real time monitoring data) food and beverage companies cannot identify opportunities to improve their water-use practices and reduce the volume and contaminant strength of their wastewater.”

Overview:

Water is an integral and strategic resource for the Ontario Food and Beverage Processing Sector, and is emerging as one of the most pressing business risks. Innovative solutions address emerging water supply and wastewater issues are critical to the future economic success of the food and beverage sector.

One major issue is that the majority of SME food and beverage processors do not have their own reliable data to properly characterize the composition of their wastewater effluent. This impacts their ability to develop an accurate profile of their effluent relative to their operations. Without this information, food and beverage companies cannot identify opportunities to improve their water-use practices and reduce the volume and contaminant strength of their wastewater. It also leaves them fully dependent on intermittent effluent testing as their only source of information which may not reflect their operational characteristics and schedule.

Quantifying the organic pollutants in wastewater is a basic requirement for the evaluation, design, operation, and controlling of the production and treatment processes. Oxygen demand is monitored for this purpose. Municipal effluent testing uses five-day biological oxygen demand (BOD5) as a measure of the organic concentration for the influent entering into the municipal sewer. The length of time required to complete the BOD5 test, combined with only periodic sampling, means that BOD results do not facilitate optimal process control and risk management.

What is COD?

Chemical Oxygen Demand (COD) is a quick, inexpensive means to determine organics in water.

The major advantages of COD analysis are:

- Results are ready in a couple of hours

- BOD results require five days

- Empirical relationship exists between COD and BOD

- Permits closer operational control of the production process

The Pilot Project:

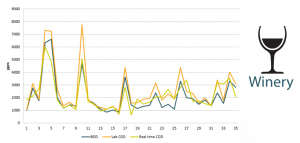

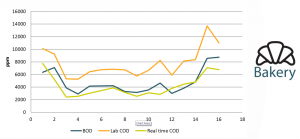

PeCOD® is a patented technology that can determine COD by measuring photocurrent charges originating from oxidation of the organic contaminants present in a water sample. Three PeCOD® analyzer units were implemented at three different facilities, representative of key food and beverage sub-sectors–a winery, a bakery and a brewery–to undertake “real-time” measurement and analysis of effluent wastewater. These real time COD analyzers were tested at each facility for a duration of 4-6 weeks. Effluent samples were collected on regular basis and sent for laboratory analysis. Laboratory analysis was not limited to standard wastewater effluent parameters but included potential method interferences such as chloride.

The objectives of the demonstrations were to:

- Characterize the facilities’ wastewater effluent composition

- Demonstrate the value of “real time” COD analysis at different food and beverage facilities

- Compare on-site “real time” analysis with standard laboratory BOD and COD analysis

- Establish relationships between laboratory results and on-site “real-time” results for each facility.

Results:

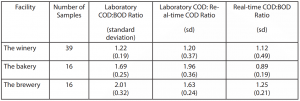

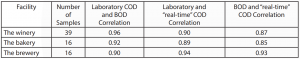

At any point in a particular food processing operation, the relationship between BOD and COD is fairly consistent (See figures). However, the ratio of BOD to COD varies widely with the type of product and is usually site specific. The COD to BOD ratio is nothing more than the COD concentration divided by the BOD concentration for the same sample. Similarly, readings from the real time COD analyzer correlated by time and date to the laboratory samples can be applied to calculate PeCOD to BOD ratios. Table 1 presents the COD and BOD ratios for all three facilities. Once the relationship has been established for each facility, the COD test can be used for monitoring and process control.

Table 1 – Preliminary COD and BOD ratios for each facility

The bakery reported the highest laboratory “real time” COD ratio which could be attributed to the high content of biological macromolecules, such as protein, lipids and cellulose, not fully recovered by the PeCOD®. In addition, unexpected high concentrations of chloride were reported in both the bakery and the brewery effluents at 960 ± 136 mg/L and 939 ± 410mg/L respectively. Chloride is the most common interference of the dichromate method and can impact test results. Therefore, the presence of high chloride concentrations in the effluent might have impacted the laboratory and “real time” COD ratio. The results from the demonstration project proved that an empirical relationship does exist between BOD5, laboratory COD, and “real time” COD. As a result, the correlations have been established for each facility (Table 2).

Table 2 – Established correlations for each site

Key Outcomes:

- Results validate the potential for fully automated and unattended on-site COD analysis using a technology such as the PeCOD®

- The PeCOD® can provide true online measurement rather than approximations

- Facilities received a more accurate characterization of their wastewater properties through the pilots

- Consistent correlations were found between BOD and both laboratory and “real time” COD results at each facility

- “Real time” COD measurements can be used to provide accurate BOD estimates within minutes

- Confirmation that cost-effective technologies can meet the sector monitoring needs

The potential benefits of real time COD measurement for the food and beverage sector are:

- Gather real time measurements which will enable plant operators to better optimize their process and manage their wastewater composition

- Reduce surcharges as a result of quick notification when limits are exceeded

- Eliminate toxic and harmful chemicals generated by the dichromate COD method

Download the full PDF here.