Aluminium Manufacturing

PeCOD® Case Study #04

Bridgnorth Aluminium is a UK-based company that makes high-quality aluminum products for the lithographic industry. Their desire to reduce water consumption and improve process efficiency, led to a 6 figure investment in a new, on-site, effluent treatment plant. Water is used throughout the facility and contributes to substantial costs for handling. Their aim is to reduce water discharge, conform to stringent water authority requirements, increase recycling of water on-site and optimize chemical treatment of all wastewater, thereby saving money at all stages.

Chemical oxygen demand (COD) is an effective way of measuring both organic pollutants and water quality. Until October 2014, a dichromate COD (CODCr) test was performed during quarterly tests carried out by the local water authority. Bridgnorth Aluminium has a COD discharge consent level set by the local water authority, and any breaches to this result in significant financial penalties.

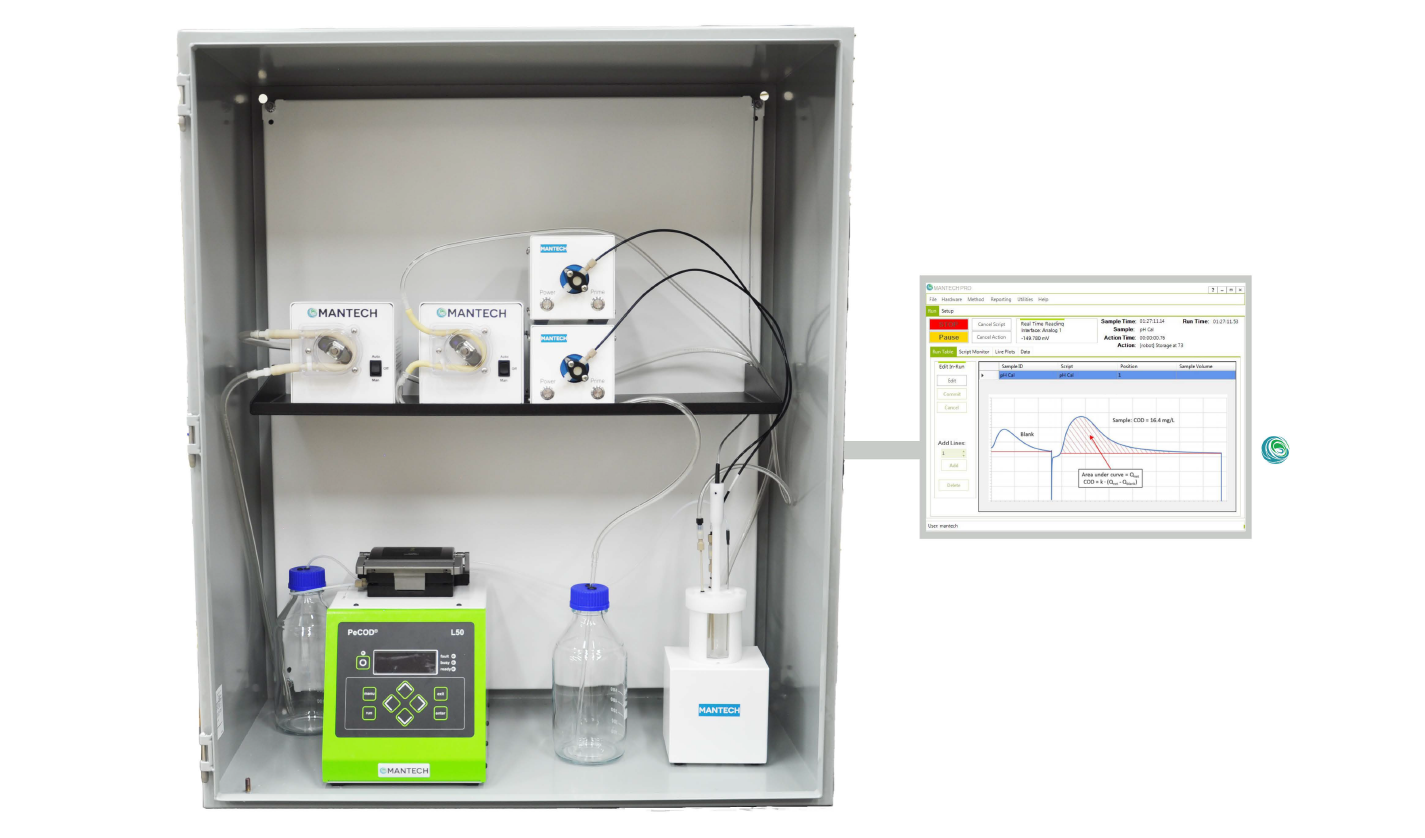

In an endeavor to minimize chemical treatment, optimize the new effluent plant, and introduce routine high-quality COD monitoring, they invested in the MANTECH PeCOD® COD Analyzer. The COD levels of various concentrations of the degreasing chemical were measured and, when plotted against the CODCr test, demonstrated a linear relationship. This relationship has been used as part of the process model to predict input COD levels into the new waste water treatment plant from the new decreasing line.

Multiple tests have been run daily since installation, and have resulted in direct cash savings brought about by optimization of the flocculation treatment process. The design of the new effluent plant has been improved as a direct result of the data generated. Bridgnorth Aluminium saw a direct return on investment (ROI) immediately and the cash savings paid for the capital expenditure of the PeCOD® Analyzer in only 3 months, with a total savings of $90,000USD per year. Lab Technicians at Bridgnorth are extremely pleased with the PeCOD® Analyzer’s user friendliness and accuracy, but most importantly the speed of the results.

An unexpected benefit that Bridgnorth found following the purchase of their PeCOD® Analyzer occurred when the data proved the existence of a hydraulic fluid leak. The MANTECH PeCOD® system was rapidly able to test water from various points around the hydraulic network and pinpoint the small leak in the hydraulic lines. The leak was quickly resolved during seasonal downtime without affecting any processes or product timelines.