Automated Rinse Stations Prevent Analysis Cross Contamination

Cross contamination between samples can negatively impact analyses and lead to inaccurate results, therefore, automated analyzers include automated rinse stations to prevent this. MANTECH rinse stations use intelligent technology with dynamic feedback viewable through the MANTECH Pro software to prevent cross contamination during water and soil analyses.

Automated Rinse Stations from MANTECH

To address challenges posed by different types of samples, MANTECH offers two rinse station styles for laboratories; the Dynamic Flow Rinse Station and the Jet Rinse Station.

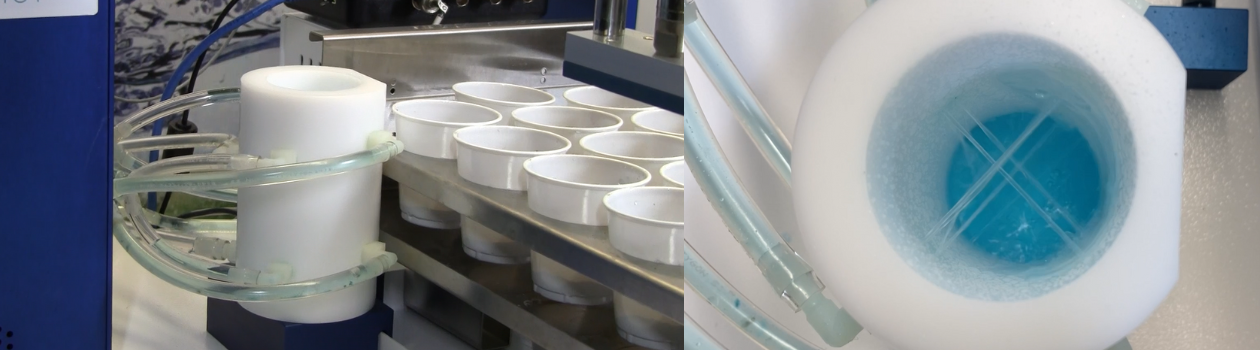

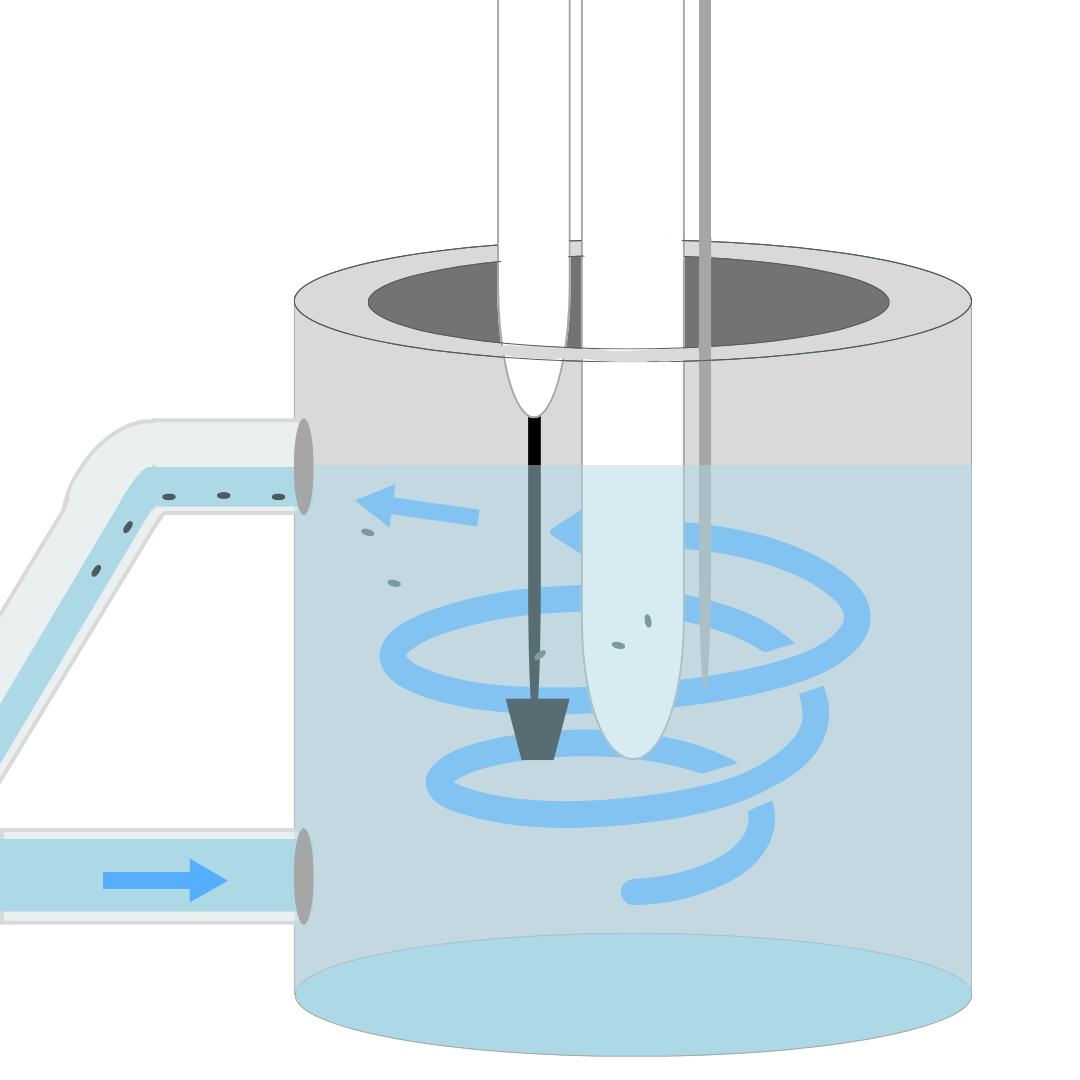

Dynamic Flow Rinse Station

The dynamic flow rinse station is the standard used for most MANTECH MT & BOD Pro systems. The station is filled with water where the probes are dipped into after sample analysis. Then, an intelligent peristaltic pump, the IntelliPeri™, pumps freshwater into a bottom port and the excess water is drained out of a top, side port. If effective draining is not available, an IntelliPeri™ pump is added to smartly pump the drain when required.

With MANTECH’s IntelliRinse™ technology, users can set a conductivity threshold in the system software for the rinse station’s water to ensure the probes are not contaminated before proceeding to the next sample. This rinse station works well for most water analyses, however there are other tests which require another type of rinse station.

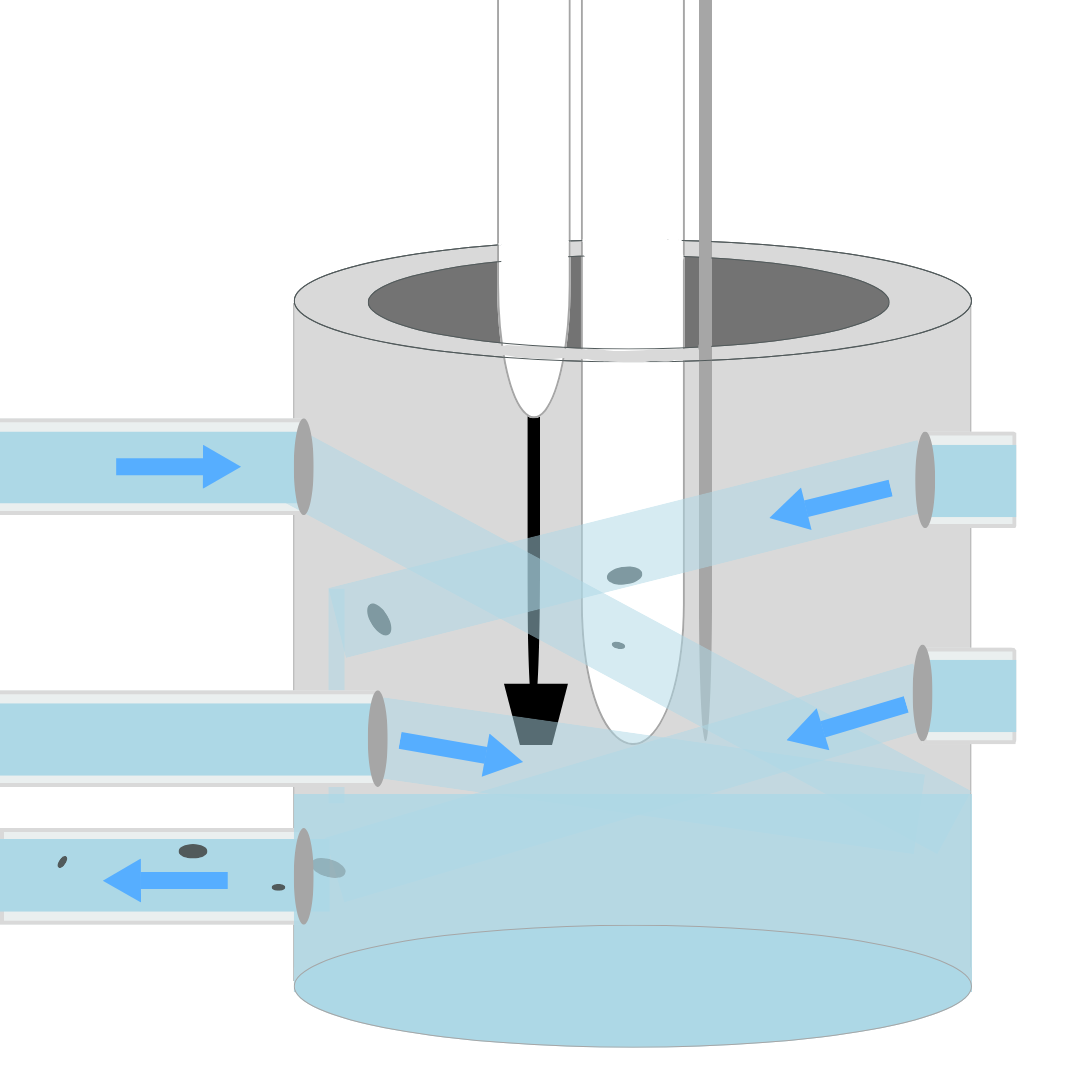

Jet Rinse Station

Samples with particles that adhere to the probes after analysis require a more rigorous cleaning procedure. An example is for soil pH analysis. This is where the jet rinse station comes in.

Unlike the dynamic flow station, the jet rinse station is not filled with water, it remains empty until the probes enter it. The IntelliPeri™ pump is used to pump high-pressure jets of water from ports around the station to remove particles from the probes. Then, an additional pump powerfully sucks waste out of a large bottom port, preventing particle build-up in the station.

IntelliRinse™ can also be used with the jet rinse station but works a little differently. Instead of measuring the conductivity of the rinse station water, it detects whether there are any contaminants left on the probes via live measurements of the probes.

Choosing the Right Rinse Station for Your Laboratory

The main factor in choosing the right station is what kind of particles are present in the sample. Soil particles tend to stick onto probes, so we recommend the jet rinse station for soils testing. For water applications, we typically recommend our standard dynamic flow station. If you’re unsure which station would work best for the tests your laboratory performs, consult our team. We’d be happy to help.