Food & Beverage Industry: Baking Soda

PeCOD® Case Study 17

Download the PDF here.

The PeCOD method for chemical oxygen demand (COD) analysis is well suited to the baking soda industry since the recovery and purification of sodium bicarbonate for the food and pharmaceutical markets requires a reliable, accurate, and fast measurement of organic matter in the product. To ensure the health and safety of consumers, low COD levels are desirable and the accuracy of analysis is extremely important. The current technique for measuring COD is not only time consuming and hazardous, but also fails to provide the level of sensitivity and accuracy that is ideal for industries with a reputation for pure, high quality products. The PeCOD® Analyzer can provide greater accuracy at low COD concentrations, which can improve product safety and help to maintain and enhance product quality.

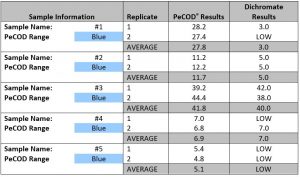

Table 1: COD values obtained for five baking soda samples using dichromate analysis and peCOD analysis

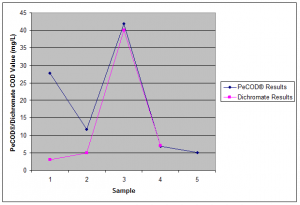

Figure 1: Plot of Dichromate COD and PeCOD COD for five baking soda samples. A strong correlation is observed between the PeCOD and Dichromate COD results.

As shown from the data, the PeCOD method can provide precise results at lower concentrations than the dichromate method. Good correlation was seen between the results, except for soda sample #1, where PeCOD produced a much higher value than the dichromate test. However, the dichromate method was only able to produce one COD value for this sample, which indicates poor reproducibility and reliability at the low concentration range. As seen in Table 1, dichromate analysis failed to consistently provide a COD result for three of the five samples, and gave no result for soda sample #5. PeCOD analysis detected COD values consistently for all samples.

These results indicate that the PeCOD® Analyzer can provide valuable product information in a fraction of the time required for the dichromate COD test, with greater accuracy and sensitivity.