An interview with Flying Monkeys Craft Brewery

Craft breweries can produce five to 10 litres of wastewater for every litre of beer that they package and sell. High in organic matter and suspended solids, the wastewater’s impact can be equivalent to adding another small town to a municipality’s water treatment burden. It’s also a challenge for brewers when they must pay water consumption surcharges and find ways to optimize their processes.

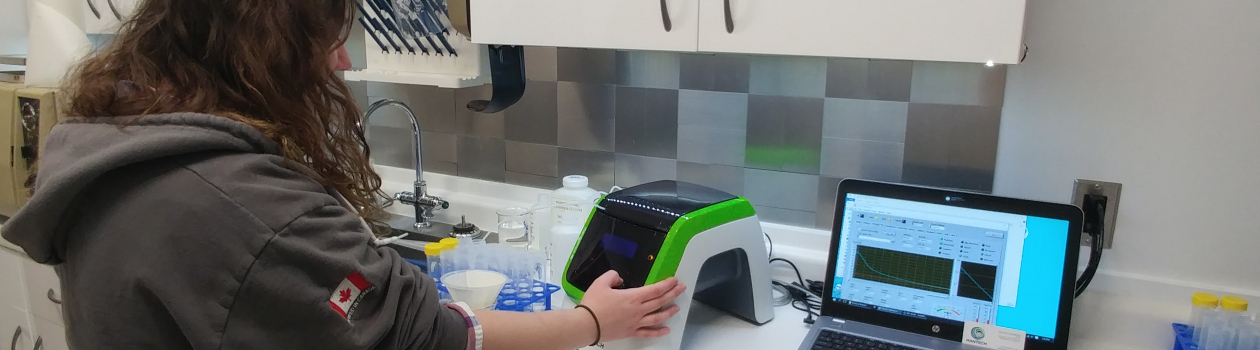

Flying Monkeys Craft Brewery in Barrie, Ontario added a Benchtop L50 PeCOD® Analyzer to their in-house laboratory in early 2017. We checked in to see how they were doing.

Q: Tell us about your experience with PeCOD® Analyzer.

A: The PeCOD system is very user friendly. I learned to use the system quickly and effectively right away. The most difficult aspect was determining the dilution factor of our variable range of effluent samples at the brewery. Once these ranges were established, we found the system to be much more simplistic. Very easy calibrations! I took great advantage of the automated calibrations, where I could set up the night prior on a timer and be ready to go whenever I required the next day.

Q: How do the PeCOD results compare to BOD5?

A: We are an industry that manufactures the perishable, living product of beer. Yeast are the key factor in the fermentation process to create this beverage. However, they have a very strong biological oxygen demand (BOD) to complete this activity. This creates a huge issue in brewery effluent, as yeast are a dominant material released into effluent. Also, we are on a set timeline to reach our market. Waiting 5 days for effluent BOD sample results is a limiting factor in the brewery industry, as BOD content is our biggest effluent obstacle. The process is continuous, and our testing needs to be reliable and quick to keep us flowing smooth. Changing to the PeCOD system was a game changer. We can now know almost immediately the range of effluent what we are releasing into the sewer system, and if we are meeting compliance for our region. It can help us regulate adjustments in our daily processes instantly if required. With a five day wait on BOD5 sampling, you do not have the luxury to be as quickly proactive within your plant; therefore, allowing yourself to be more vulnerable to receive regional compliance fines.

Q: What have you learned about your wastewater stream since installing the system?

A: We have learned a lot regarding our wastewater stream since adopting the PeCOD system. We have come to recognize the effluent patterns of specific beer manufacturing and packaging procedures, as our wastewater has variability dependent on the processes occurring. We have determined how to pair certain activities together to balance our daily effluent. We have started to see the monthly and seasonal patterns in our effluent as well. We have been able to properly characterize our processes effluent composition and have developed ranges of high/low COD/BOD parameters. We have also developed which parts of the process to side stream completely. Overall, this technology permits closer operational control of the production processes we have in relation to the wastewater created.

We have been developing an empirical relationship between PeCOD and BOD volumes in our unique effluent. We anticipate that this information will allow us to forecast where our effluent levels will be prior to the brewery activities occurrence. Hopefully, we will be able to predict how our effluent will change as our company expands and as beer production increases overall. We want to be proactive and plan accordingly to avoid effluent surcharges and issues beforehand. We have noticed that a lot of breweries want to remain quiet regarding the issue of high BOD in the effluent. We want to take the responsibility of all factors of our product and set an example for our industry.

Q: Have you noticed any process optimization?

A: We have noticed a few optimizations of our processes with the use of the PeCOD. Most notable is the laboratory turnover time between sampling, and number of samples we can perform in a daily session dramatically increased. Another optimization in relation to the recognized effluent patterns of specific beer manufacturing and packaging procedures, we have determined which activities should be paired together to balance our daily effluent. We have also been able to move away from old analytical techniques for chemical oxygen demand (COD) testing, meaning the dangers of dichromate are no longer an issue for us. We also no longer require additional hazardous waste storage and removal for this chemical. With assistance from the PeCOD unit, we have also been able to examine recent technologies, (such as a waste dehydrator unit, centrifuge, water polishing technologies), and analyze if the technology suits our needs prior to purchase. We have begun to identify key inefficiencies in our beer manufacturing equipment and SOP’s as well and are actively improving these to benefit both our plant operation and wastewater condition overall.

Q: Have you seen a reduction in water use?

A: Water is key ingredient in beer. If we do not take responsibility to clean it up, eventually we will not be enjoying the same quality in beer we do today. The reduction of water consumption has been a large part of our effluent reduction program overall at the brewery. The PeCOD has assisted greatly in bring awareness to all our operators and how their water usage during brewery activities can influence the overall picture of our end effluent. Quite a bit of our processes still requires a lot of manual labour, and educating the operators has significantly aided to the reduction of water volumes spent overall. As the amount of beer production has increased during the last few years, keeping excess water consumption volumes minimal is valuable to our business.

Q: Have you experienced municipal surcharges?

A: We have been working alongside our region with sampling and testing. This allows us to establish that results sampled and tested by the city and ourselves are unbiased and true. We have heard various stories regarding situations with improper sampling and unnecessary compliance fines handed to breweries unable to check themselves. With having the PeCOD on site, our business can feel more secure with the effluent parameter results determined.

Contact Us About Your Wastewater Challenges