Monitoring Chemical Oxygen Demand and Biochemical Oxygen Demand in Craft Brewery Wastewater

Craft breweries are a popular and rapidly growing industry in North America which presents a unique set of challenges regarding wastewater treatment and production via the brewing process. Craft brewery wastewater is generated in large volumes and is often high in sugar, alcohol, solids, and may not have a neutral pH. Treatment of this wastewater is a concern due to its high organic content, potentially overloading the municipal capacity of treatment plants in smaller towns. Additionally, discharge requirements may lead to surcharges, creating a need for process optimization, including water reuse implementation.

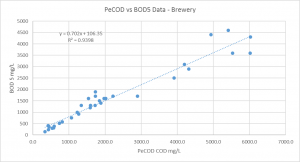

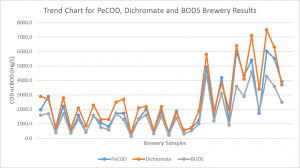

Biochemical oxygen demand (BOD) and chemical oxygen demand (COD) are two parameters commonly used to monitor wastewater quality and organic content, prior to treatment. The PeCOD® Analyzer has proven to be a valuable tool in accessing brewery wastewater organic load, and provides real-time results using an environmentally green and safe method. In conjunction with MANTECH, Econse Water Purification Systems has implemented the PeCOD® Analyzer for use with their Brü Clean System, a modular management and treatment system, specifically designed for craft breweries. The PeCOD® Analyzer has demonstrated a strong correlation between the traditional BOD5 test, and photoelectrochemical Chemical Oxygen Demand (PeCOD), as shown in Figure 1 and Figure 2, below.

Figure 1: A linear regression of PeCOD® COD Analyzer results vs BOD5 results. A strong correlation is observed shown by an R2 value of 0.94.

Figure 2: Trend chart for PeCOD® COD Analyzer results, Dichromate COD (CrCOD) results, and BOD5 results for brewery wastewater samples. A similar pattern is observed for each trend line.

In many cases, 300mg/L of BOD is the regulatory discharge limit for industrial wastewater. Therefore, the ability to predict BOD from PeCOD® derived COD is a convenient tool to accurately monitor organic load, optimize brewery processes and to prevent unnecessary surcharges. The MANTECH PeCOD® COD Analyzer is an integral part of the Brü Clean System; together they have reduced up to 75% of wastewater generated by the brewing process. As quoted by the Co-Founder, and head of Business Development for Econse, Derek Davy,

“We can accomplish in a few minutes what other companies take weeks or months to do and this lets us move straight to effective treatment solutions for our clients.”

Download the PDF here.