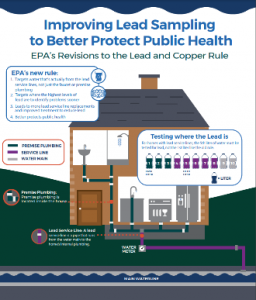

How you noticed an increased demand in lead and copper testing? This is likely due to the Lead and Copper Rule Revisions by the US Environmental Protection Agency.

Lead in Drinking Water

Old, leaching pipes can cause lead to enter the water we drink, which ends up in our bodies when we cook our food or prepare formula for babies. Lead is a highly toxic pollutant that can damage neurological, cardiovascular, immunological, developmental, and other major body systems (and is especially harmful to pregnant women and children’s development). In recent years, there have been a number of devastating water crises in communities through the United States (i.e. Flint Water Crisis and Benton Harbour, MI Water Crisis) triggering government agencies, such as the EPA, to respond for the safety of public health.

What is the LCR & LCRR?

The Lead and Copper Rule (LCR) is the rule set out by the Environmental Protection Agency (EPA) that regulates the monitoring and control of lead in drinking water. The nearly 30-year-old rule included deficiencies the Lead and Copper Rule Revisions (LCRR) aim to fix. The revised rule strengthens the existing LCR by:

- Using science-based testing to better locate elevated levels of lead in drinking water.

- Establishing a trigger level to jumpstart mitigation earlier and in more communities.

- Driving more and complete lead service line replacements.

- Requiring water systems to identify and make public the locations of lead service lines.

These infographics outline how the revised LCR reduces lead exposure in both small and large communities.

“The revised LCR is a substantial milestone in our continued collective efforts across the country to remove lead from our communities,” said Wisconsin State Senator Robert Cowles.

LCRR’s Impact on Utilities & Laboratories

Increased Metal Screening and Monitoring Frequency

The revised rule requires utilities to increase the number of metal screening and monitoring frequency, therefore laboratories will recognize an influx of demand for performing metal digestion. The LCRR now requires that community water systems test for lead in drinking water in elementary schools and childcare facilities that they serve. Also, the LCRR has a newly defined lead trigger level (TL) of 10 < P90 ≤15 µg/L that triggers additional planning, monitoring, and treatment requirements.

Stricter Collection Procedures

The US EPA has defined a new series of procedures that utilities must perform when collecting samples for metal screening analysis. The LCRR adds a requirement of collecting samples in wide-mouth bottles. More significantly, collection of the fifth-liter sample in homes with lead service lines (LSLs) after water has sat stagnant for a minimum of 6 hours and maintains first liter sampling protocol in homes without LSLs.

Timely Results

The revised rule outlines new specifications for utilities to report timely results are being implemented to enhance transparency and empower communities through information. Notification of tap sample results over 15 ppb will occur within 3 days however, under this threshold will require notification within 30 days. Notification of systemwide action level exceedance will occur within 24 hours and provide educational materials within 60 days.

Regulated Water Quality Parameters (WQPs) & Monitoring

The US EPA will require laboratories to conduct analyses for regulated water quality parameters at specified monitoring points and frequencies. The defined water quality parameters include pH, alkalinity, and turbidity. Systems serving ≥ 50,000 people must conduct regular WQP monitoring at entry points and within the distribution system, whereas smaller systems must continue WQP monitoring until they no longer > lead and/or copper AL for two consecutive 6- month monitoring periods. To qualify for reduced WQP distribution monitoring, P90 must be ≤ 10 µg/L and the system must meet its optimal water quality parameters (OWQPs).

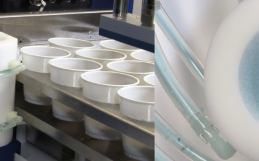

Options for Metal Digestion Screening

Metal digestion screening is an analysis that measures both pH & turbidity. If the screening results indicate ≥1 NTU the sample will need to be digested. This screening is approximately 90 seconds per sample in comparison to conducting a 2-hour combustible and toxic digestion on all samples. The value of performing this screening saves both time and money as well as improving health and safety.

With the introduction of the LCRR, utility and laboratory personnel will be stretched thin to compensate for the increased testing requirements. It is crucial that this additional workload be mitigated. Supported through a number of case studies and research, the most cost-effective manner to increase throughput is through automation. MANTECH offers a variety of options with capacities ranging up to 520 samples per batch depending on the level of throughput and automation desired.

| MT3 | MT30 | +T-10 Turbidity | |

|---|---|---|---|

| Capacity | 1 sample – manual probe dip | 112 – 560 samples | – |

| Rinsing | Manual | Dynamic IntelliRinse | Low-volume flow cell with automated rinsing |

| Sample Volume | 30mL | 30mL | |

|

All MANTECH Pro software-controlled titrations and database. |

Inquire About Metal Digestion Screening

Learn more about the LCRR: https://www.epa.gov/dwreginfo/lead-and-copper-rule