Industrial Waste Water

PeCOD® Case Study #02

Clean Harbors is an industrial wastewater treatment facility in Guelph, Ontario. The facility utilizes highly refined, chemical precipitation processes, which remove heavy metals, suspended solids, and organics to generate safe effluent for discharge into municipal sewer systems. Wastewater is treated to meet municipal discharge requirements for biochemical oxygen demand (BOD5). Since BOD is a 5-day test, the results cannot be used to continuously monitor organic load. Chemical oxygen demand (COD) is used as a fast assessment of organic contamination. A correlation study is then used to determine the relationship between COD and BOD5.

The PeCOD® COD method is well suited for use in an industrial wastewater treatment facility due to its rapid analysis and safe operation. COD monitoring offers the operational feedback necessary for optimizing production, thereby reducing the consumption of raw materials, energy, and sewer discharge costs.

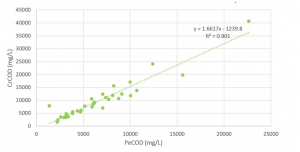

Figure 1: A scatterplot demonstrating a strong correlation between PeCOD® COD and CODCr for incoming hauled wastewater from a variety of industries.

Results in Figure 1 are from a single Clean Harbors treatment plant, servicing multiple different industries, including automotive, manufacturing, primary steel, chemical, and dairy facilities. Samples were prepared by centrifugation to settle solids then mixed in a 1:49 ratio with RED range PeCOD® electrolyte. The soluble COD was analyzed by the PeCOD® COD method and compared against the dichromate COD (CODCr) and BOD5 methods.

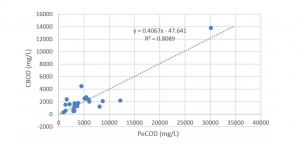

Figure 2: A scatterplot demonstrating a strong correlation between PeCOD® COD and BOD5 for composite daily sampling of treated wastewater effluent discharged to the

The objective of this study was to determine if a correlation exists between PeCOD® COD and traditional methods (e.g. CODCr and BOD5). The results indicated a strong correlation between PeCOD® COD and CODCr for incoming hauled wastewater (Figure 1). Similarly, the results from treated wastewater samples taken from various industries, demonstrated a strong correlation between PeCOD® COD and BOD5 methods (Figure 2).

Upon completion of the study, Clean Harbors invested in the PeCOD® COD Analyzer, complete with autosampler, immediately putting it into production and replacing the CODCr method. The key advantage for Clean Harbors in adopting the PeCOD® COD Technology, was the speed of the test. The wastewater treatment facility can obtain critical information on incoming loads within 15 minutes, allowing for quick decision making and more efficient treatment. Prior to unloading, a COD measurement is obtained using the PeCOD®. If the result is above the acceptable limit, the truck can immediately be diverted to an incinerating plant. However, due to the nature of the CODCr method, results are not available for approximately 3 hours. In that time, the truck would have unloaded the wastewater and left the facility. Avoiding this time delay, eliminates the requirement for subsequent storage and hauling costs. Furthermore, incoming wastewater that is below plant sewer discharge limits can be quickly discharged, thereby saving on chemical and energy costs. The PeCOD® also provides a reliable estimate of BOD, which is required for compliance with municipal standards. Historically, the BOD results were received by Clean Harbors 8 days after sampling. Now the facility can obtain a daily real-time BOD estimate, ensuring peace of mind with regards to their treated discharge effluent.

By investing in a PeCOD®, Clean Harbors continuously monitors the organic load of influent and effluent wastewater, to optimize treatment processes. The speed and accuracy of the PeCOD® COD method has led to substantial financial savings, thereby increasing profitability. In addition, Clean Harbors improved the health and safety of the workplace and their employees by eliminating the use of dichromate, mercury, and concentrated acid required with the CODCr test. With the PeCOD® investment, Clean Harbors demonstrated financial, sustainable, and environmental stewardship, which benefits the community as a whole.