Improved Wastewater Treatment & Mill Performance With New COD Monitoring Technology

The Nordic Wood Biorefinery Conference will be taking place March 28-30, 2017 in Stockholm, Sweden. An abstract presentation authored by partners from VTT, Kemira, FPInnovations and MANTECH has been accepted and will be presented during the conference. The PeCOD® Analyzer has the ability to enable pulp and paper mills to improve effluent treatment process and to optimize chemical programs, leading to proper chemical dosage (not over or under doses) and lower energy requirements for treatment. The strong correlation between the PeCOD® Analyzer and the dichromate method suggests that the PeCOD® Analyzer could be a valuable tool to help both in-mill operation optimization and improved waste water optimization while protecting public health and the environment.

Download the abstract here.

Improved Wastewater Treatment & Mill Performance with new COD monitoring Technology

Stephanie Horner1, Robert Menegotto1, Pauliina Tukianien2, Antti Grönroos2, Marjatta Piironen3, Sakari Halttunen3, Iiris Joensuu3, Serge Genest4, Brian O’Connor4

1MANTECH, Canada, 2VTT, Finland, 3Kemira, Finland, 4FPInnovations, Canada

Abstract

The objective of this transnational project is to determine novel concepts for the reduction of recalcitrant chemical oxygen demand (COD) in water intensive industries, with a focus on the pulp and paper industry. A new COD method, photoelectroChemical Oxygen Demand (PeCOD), is being utilized to help evaluate the COD reduction of the new water treatment technologies and methods at various stages of the pulp and paper wastewater treatment process. A comparison of COD results using PeCOD and dichromate COD (CODCr) method were conducted for many different effluents from kraft and mechanical pulp mills. Studies were completed in multiple laboratories with several different PeCOD configurations. The PeCOD method demonstrated a strong correlation to CODCr method for all effluent sample types and indicated excellent reproducibility for comparative results.

Introduction

Pulp and paper mills produce a large volume of wastewater and residual sludge, which is a growing concern due to increasing environmental regulations becoming stricter. Experts are looking for solutions to reduce their fresh-water intake and ultimately achieve close to zero liquid discharge. The challenges of these solutions include: high organic concentrations in production and wastewater effluent, operation costs, performance, and impacts to the environment. Additionally, the push for stricter COD effluent discharge regulations suggests a safer, faster and more robust COD monitoring tool is essential for process optimization and discharge compliance.

Since mid-2013, the PeCOD method has been proven and trusted a green, safe, fast and accurate alternative to the CODCr method for a kraft Chilean Mill. The 15 minute PeCOD results led to a reduction in hypochlorite used for bleaching, with no loss of product quality. This has resulted in lower organics in the waste water plant and further reductions of chemicals and energy used for treatment. The total savings over 12 months netted $3 million dollars (US), a 3-day return on investment for the PeCOD unit. The strong CODCr to PeCOD correlation at the Chilean pulp and paper mill was reinforced with a range of effluents both kraft and mechanical pulp mills in this project.

Experimental Methods

The PeCOD method eliminates the use of mercury, dichromate, and concentrated acid, which are found in the CODCr method. The core of the PeCOD nanotechnology utilizes the high oxidation potential of UV irradiated TiO2 nano-particulates to fully oxidize all present species. The PeCOD only measuring soluble COD (sCOD), therefore suspended solids of >50 µm are removed prior to sample analysis. The testing range is 0.7mg/L-15000mg/L of COD, yet incorporating dilution can extend this range.

There were two PeCOD configurations utilized in this project, automated L50 and online L50. Both use the same PeCOD technology and consumables, but are setup to operate under different conditions.

Results and Discussion

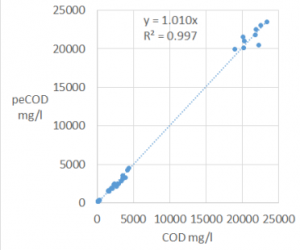

The PeCOD and CODCr tests conducted on pulp and paper mill effluents, at Kemira3 and FPInnovations4 laboratories, displayed strong correlation with r2 values ranging from 0.92-0.99 on both PeCOD configurations. The results below from Kemira3 in Figure 1 showcase a standard deviation of 1% and an r2 of 0.997 between an automated L50 PeCOD and CODCr.

Figure 1: Automated L50 PeCOD versus filtered (0.45 µm) CODCr for multiple sampling locations of a thermomechanical pulp and paper mill.

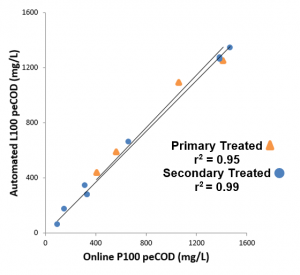

FPInnovations4 had very similar results to that of Kemira3, however they experienced success with both PeCOD configurations. The comparison of PeCOD results between the automated L50 and online L50 is illustrated in Figure 2. This reinforces suspended solids do not contribute to the total COD.

Figure 2: Comparison of automated L50 PeCOD and online L50 PeCOD for primary (orange triangle) and secondary (blue circle) treated Kraft mill effluents.

On average, where differences existed, PeCOD reported slightly higher COD results than CODCr. This is potentially due to the PeCOD more effectively oxidizing recalcitrant COD present in treated effluent samples.

Conclusions

The PeCOD has been proven to safely and effectively improve effluent treatment processes and optimize chemical programs in pulp and paper mills. The strong correlation between PeCOD and CODCr suggests it could be used as an online monitoring tool for in-mill operation and wastewater treatment optimization. Its green and safe technology will also protect laboratory professionals, public health and the environment.