Chemical Oxygen Demand Monitoring for Soap and Detergent Manufacturing

Soap and detergent manufacturing generates waste water that is highly contaminated with organic compounds, significant concentrations of oil, grease, and surfactants. These compounds are a concern for receiving waters due to the formation of foam, and potential toxicity to microbial habitats and wildlife. Process water treatment typically involves dissolved air flotation, chemical coagulation-sedimentation, and biological treatment by activated sludge process.

Download the full PDF here.

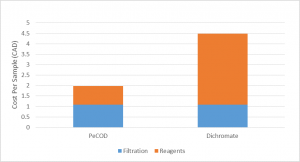

Due to the hazardous nature of the Dichromate COD Method, and recent restrictions on Dichromate and Mercury, a soap and detergent manufacturing facility in Sri Lanka purchased a PeCOD® Analyzer for effluent monitoring. The Laboratory (L50) PeCOD® Analyzer was used for grab sampling at multiple locations in the plant to obtain rapid and reliable results. Figure 1 compares photoelectrochemical Chemical Oxygen Demand (PeCOD) COD and Dichromate COD at the final effluent. Samples were filtered through a 1.5 micron filter prior to analysis, however the suspended particles presented a positive interference with the dichromate method which lead to an over-estimation of COD. Soluble Chemical Oxygen Demand was a more accurate measure of contamination for this sample matrix, based on the ratio of total dissolved and total suspended solids.

Figure 1: PeCOD® COD and Dichromate COD values for sample collected over 5 days at the final discharge.

“The PeCOD values are capturing only soluble COD which is in line with true COD” – Laboratory Operator

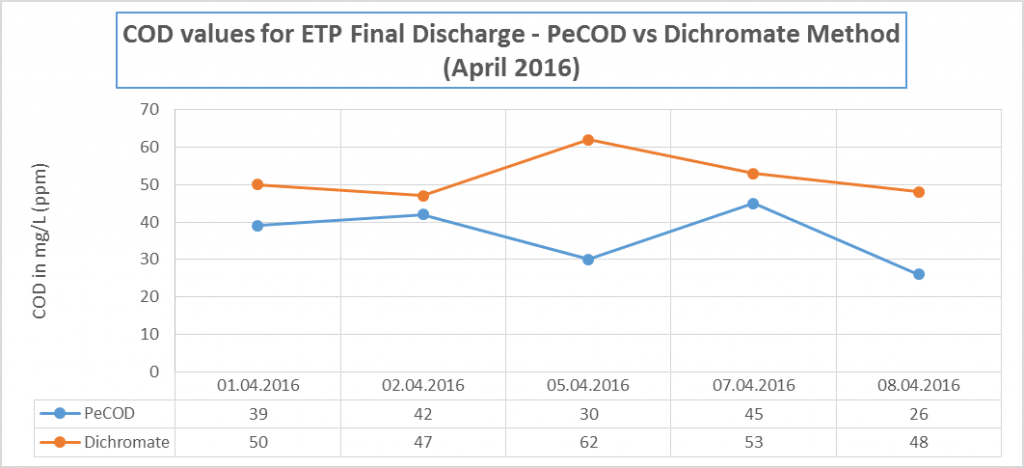

Figure 2 below shows the improved cost per sample by switching to the PeCOD COD method. The rapid Chemical Oxygen Demand analysis made it easier for the laboratory operators to obtain results and provide feedback on treatment optimization. This large scale health and wellness company is focused on environmental sustainability and having a small footprint. Implementation of the PeCOD® technology has eliminated hazardous chemicals associated with Dichromate COD while being safe for the operators and the community. Successful outcomes from this capital purchase have led to expanded PeCOD usage at additional facilities within the company.