BOD Automation: Step by Step

Due to the labor-intensive nature of the 5-day Biochemical Oxygen Demand (BOD) test, BOD automation helps mitigate the manual tasks analysts need to perform. Here’s how MANTECH’s BOD automation solutions integrate and replace manual tasks in the BOD process.

Equipment Preparation

To start, the analyst makes dilution water by mixing nutrients and deionized (DI) water. Next, the analyst calibrates the DO meter and probe using a 300mL bottle filled with DI water.

With BOD Pro software, MANTECH’s BOD Pro analyzer performs automatic calibrations of the DO meter and probe before it measures initial and final DO readings.

Sample Preparation & Transfer to Dilution Bottles

Then, the analyst tests the temperature, pH and chlorine of each sample before BOD analysis. If sample pH is between 6 and 8, the analyst adjusts the pH to between 7 and 7.2 using either 1N sulfuric acid or 1N sodium hydroxide. Since chlorine can interfere with BOD results, the analyst dechlorinates any sample with residual chlorine. Sodium sulfite is typically used for this. After, the analyst aliquots the sample into dilution bottles at different volumes.

MANTECH’s sample transfer analyzer measures pH and chlorine, adjusting the samples as needed using intelligent pumps that deliver the necessary reagents. Next, this analyzer accurately aliquots the samples in volumes determined by the analyst beforehand. Typically, cleaner samples like effluent need more sample volume compared to dirtier samples like influent or industrial samples.

Bottle Preparation for Initials

Afterwards, the analyst prepares bottles for blanks, seed control and GGA standards (QC standards). They also prepare bottles by adding dilution water, seed and/or inhibitor to the sample volumes they aliquoted earlier. Samples that are not strong enough to deplete themselves (i.e. clean effluents) may require seed addition. If performing Carbonaceous Biochemical Oxygen Demand (CBOD), the analyst will add a nitrification inhibitor.

Utilizing intelligent pumps which communicate bi-directionally with BOD Pro software, the BOD Pro analyzer adds dilution water, seed and/or inhibitor to BOD bottles according to what is indicated in the run (whether seed is needed and/or if performing CBOD) that was set up in the software.

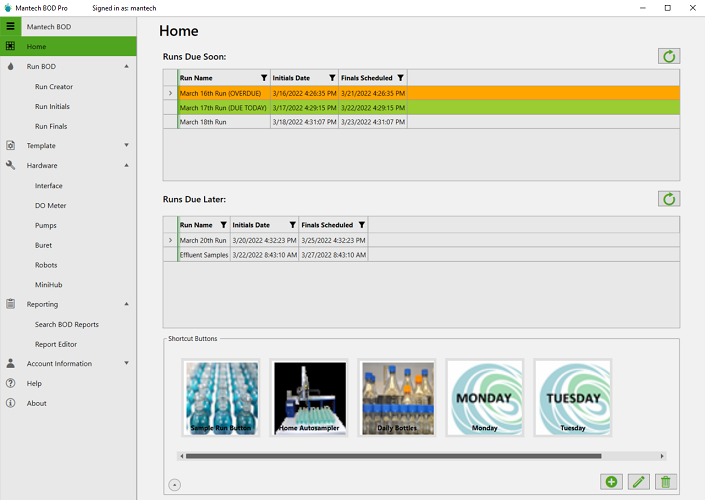

DO Readings and Incubation

Once all the bottles are prepared, the analyst measures and records the initial DO of the samples. Next, the analyst places the sample racks into the incubator for 5 days. After 5 days of incubation, the analyst measures and records the final DO of the samples.

MANTECH’s BOD Pro analyzer automates initial and final DO readings, recording the data into BOD Pro software. BOD Pro provides accurate DO measurements via its proprietary delta mg/L O2/delta time user defined stability criteria. The software also tracks the incubation period so when it’s time to read finals, the run is already waiting to be queued up in the home screen.

Calculations & QC Checks

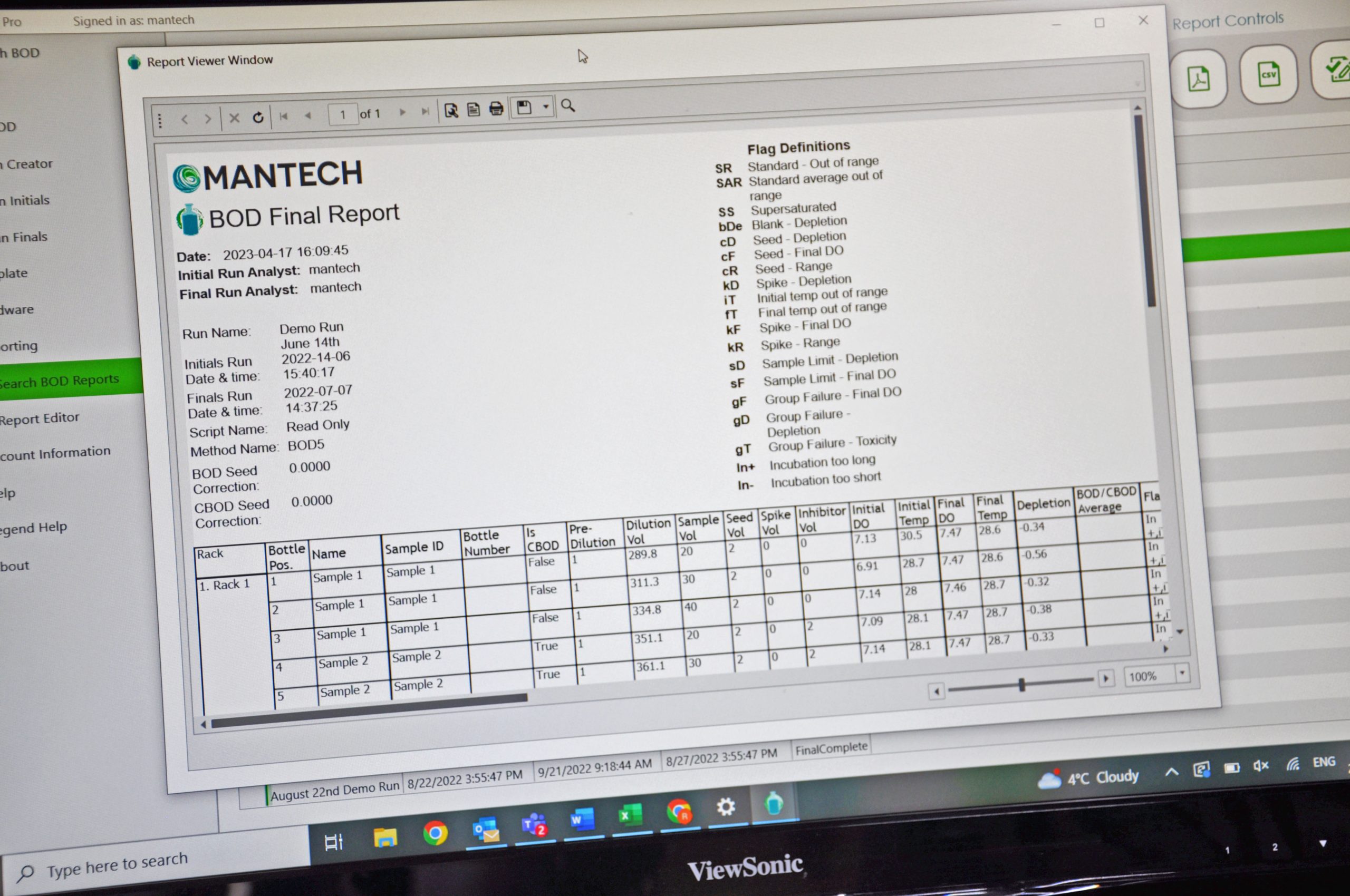

Lastly, the analyst performs BOD calculations, QC checks and records the data in a final report. The analyst will also make note of any QC issues.

BOD Pro software performs BOD calculations, checks QC and generates a final report. The software flags any QC issues in the report using short abbreviations for analysts to easily reference.

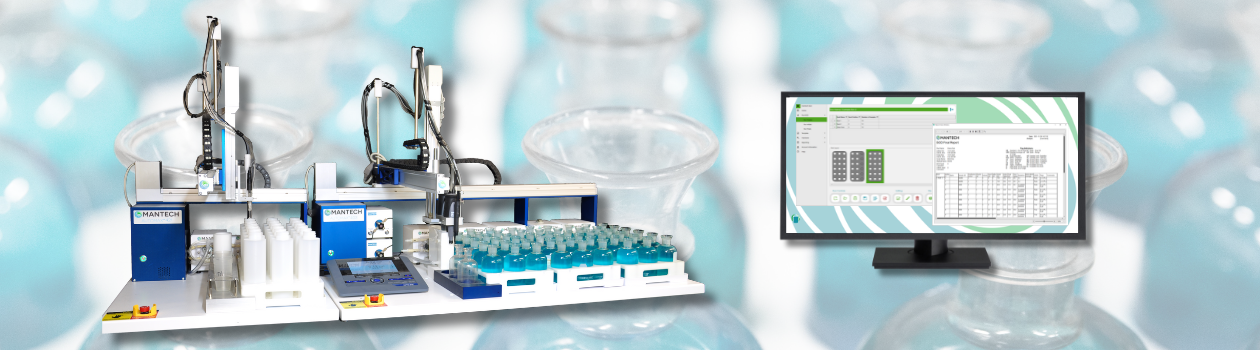

Highly Configurable BOD Systems from MANTECH

With MANTECH’s automated BOD Pro analyzers, users can configure their system to meet specific requirements based on desired level of automation, throughput and available bench space. These systems are easily upgradable as the needs of the lab change. Helpful benchtop tool add-ons are also available.

Automation Options

MANTECH’s BOD Pro analyzers have capacities of 12-108 bottle positions. However, users are not restricted by the number of positions as unlimited batch sizes can be made in the software. Users receive alerts via software prompt or via email when it’s time to switch racks. Add a separate calibration/QC rack to maximize sample rack space. To accommodate different lab bench depths, MANTECH offers autosamplers with either a 24-inch depth or 29-inch depth. The length of the autosampler depends on the desired bottle capacity.