Pulp and Paper

PeCOD® Case Study #03

The pulp and paper industry utilizes wood as raw material to produce pulp, paper, card board, and other cellulose based products. Pulp and paper mills produce large volumes of wastewater and residual sludge which presents a number of challenges with regards to treatment and discharge. Contaminants in pulp and paper waste streams often include effluent solids, sediments, absorbable organic halides (AOX), chlorinated organic compounds, chemical oxygen demand (COD), and biochemical oxygen demand (BOD). In many cases, the delignification and wash pulp steps require excessive volumes of bleaching chemicals which contribute significantly to the higher COD contamination typical of this wastewater.

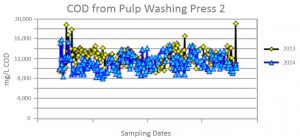

A Chilean multi-national paper company invested in a MANTECH PeCOD® COD Analyzer to improve the health and safety of operators and to significantly reduce analysis time. By continuously monitoring COD levels (less than 15 minutes), the mill was able to optimize the pulp process and reduce the consumption of bleaching chemicals. The decrease in chemical consumption resulted in a lower amount of organics to treat, and in turn, reduced treatment chemicals, energy and discharge fines. Figure 1 demonstrates the reduction in COD levels between 2013 and 2014, since implementing the PeCOD® COD Analyzer. The pulp and paper mill saved greater than $10,000 (USD) per day by optimizing treatment processes, reducing energy usage and decreasing chemical usage. Savings of 3 million US dollars per year yields a return on investment of just 3 days. The PeCOD® COD Analyzer has provided critical information to the operators while improving health and safety to the community and the environment

Figure 1: A graph of PeCOD® COD results from the pulp washing step at a pulp and paper mill. Wastewater samples were collected and analyzed over a two-year period.

Another PeCOD project at a facility located in Quebec, Canada, focuses on improving the sustainability of the forestry industry by monitoring effluent wastewater produced by the pulp and paper industry. The traditional dichromate method has historically been used to monitor COD levels for this purpose. However, due to PeCOD’s analysis speed and environmentally friendly nature, mills can optimize their processes and improve the health and safety of their staff in a safe and timely manner. Validation studies for the PeCOD COD method are important for reporting purposes, as the traditional dichromate method is the industry standard for COD analysis.

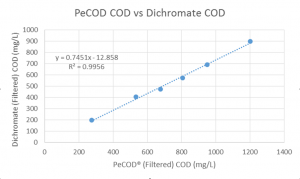

The facility in Quebec is utilizing the PeCOD analyzer to test a range of effluent samples produced by an onsite mini-pilot plant, in addition to samples from established pulp and paper mills. Figure 2 represents effluent wastewater samples measured for COD by both the PeCOD and the dichromate method. A strong correlation is observed between PeCOD COD and dichromate COD (R2 = 0.9956). This correlation indicates that the PeCOD technology is suitable for use in the pulp and paper industry as it is a reliable predictor of the regulated dichromate method for COD.

Figure 2: A linear regression of PeCOD® COD Analyzer results vs Dichromate COD results. A strong correlation is observed shown by an R2 value of 0.9956.

The PeCOD analyzer uses nanotechnology encompassing titanium dioxide, a powerful oxidizer with a higher oxidizing potential than dichromate. The results shown above support this fact, as PeCOD COD measured slightly higher than dichromate for each of the samples. It is important to note that sample preparation for COD measurement by both PeCOD and dichromate made use of a 35uM filter to remove any solid particulates from analysis and is thus a measure of soluble COD.

Both presented cases reduced COD analysis time significantly while validating the PeCOD with the traditional dichromate method. The first pulp and paper mill reported a decrease in response time by 95% and a decrease in cost for running the COD test by 66.4%. As a result, the PeCOD® COD Analyzer plays an important role in the pulp and paper industry by providing valuable financial savings to the mill, promoting process optimization, and supporting environmental efforts by establishing a green COD method; all of which contribute to forestry sustainability.

Author: Katelyn Wanka, B.Sc., M.BINF., Quality Control and Research Chemist at MANTECH Inc.

Download the full PDF here.