Sewer Use By-law Enforcement: BOD Pre-Screening

PeCOD® Case Study #16

Wastewater treatment plants are designed to process an expected average organic loading in the raw influent. This is determined by the population size and industrial activity within the plant’s service area. Growth of these factors result in a higher cost of treatment. Eventually the treatment plant is forced to build upgrades to handle the increased load and plan for future population growth, often at great cost to the municipality.

To recover some of these costs, many municipalities enforce sewer-use by-laws to limit excessive loading, with financial consequences for those who do not comply. Municipal wastewater contains a mixture of widely varying waste streams originating from residences, businesses, and industries. The individual waste streams are typically classified into two categories: sanitary waste and process waste. The latter is produced from industries such as manufacturing and contains the most variation. It also has the greatest potential to quickly increase as a business expands, therefore the sewer-use by-laws typically target large industrial contributors of process waste.

Enforcing these sewer-use by-laws is a tedious and difficult task which targets industrial sectors to determine companies that are in violation of the by-law. This is conducted by sampling their process wastewater, then establishing an agreement with the company to pay a surcharge to the municipality for the use of the sewer. This surcharge is based on concentrations of water quality parameters in the waste stream, with the goal of recovering the same amount of cost the company is inducing at the treatment plant. Often the most critical water quality parameter included in a surcharge agreement is Biochemical Oxygen Demand (BOD), measured by the BOD5 test (a 5-day incubation period to determine oxygen depletion rates). Application of BOD measurement with wastewater sample matrices requires sample dilution to allow for accurate measurement of the oxygen depletion during the incubation period. Determining the optimal dilution ratio is difficult, as the accuracy is dependent on both the range of the instrumentation measuring oxygen levels, and assuming the aliquot of the wastewater sample is representative.

Many laboratories performing BOD analyses are limited by their sampling capacity, daily sampling requirements, and the rapid degradation of organic samples. Due to these factors, they often have a limited number of dilution attempts they can complete per sample, potentially resulting in a misrepresentation of the true organic load. Currently the municipal government in El Paso, Texas uses CBOD5 (Carbonaceous Biochemical Oxygen Demand) analysis for their industrial wastewater monitoring program, which includes sewer-use by-law. It was recently discovered that they had been under-reporting the organic loading from high-strength waste streams due to this challenge with dilutions, resulting in lower recovered costs for the treatment plant. In the past, a set of dilutions for each industry had been established based on historical CBOD analyses, however the municipality found these ratios were no longer accurate due to increased industry activity and higher variation in the organic load. To resolve the issue, they integrated a new method to help indicate potential CBOD concentration to optimize the dilution ratio required for CBOD analysis.

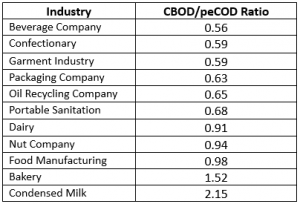

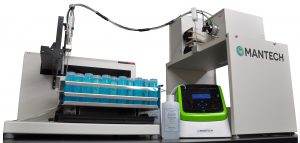

The new method that was integrated for CBOD level indication measures Chemical Oxygen Demand (COD), which historically has a strong correlation with CBOD for wastewater sample matrices. The municipal laboratory in El Paso already had a standard method in place to determine COD through a dichromate digestion, however it requires a few hours to complete, produces hazardous waste, and presents a great health risk to operators. The laboratory decided to adopt the use of the PeCOD® Analyzer, which measures COD through a rapid 15 minute photoelectrochemical oxidation (PeCOD) using green non-hazardous reagents. To further accelerate the pre-screening process, the Automated PeCOD® Analyzer model was implemented. It features automated sample preparation and the ability to perform analysis on over 70 consecutive samples. During the initial stages of PeCOD implementation, the municipality established a set of ratios reflecting the industry specific relationship between CBOD and PeCOD, displayed in Table 1. These ratios are now used for a quick conversion of PeCOD values to estimate CBOD, which helps to determine the optimal CBOD dilution for accurate measurement.

The implementation of the PeCOD pre-screening method has allowed the municipality to accurately bill industries for their wastewater discharge with only one CBOD dilution. This has dramatically increased both the efficiency of the wastewater monitoring program and the recovered costs for the treatment plant operation. Additionally, the full system automation has freed up operator time within the department allowing for more resources to be dedicated elsewhere.

Download the PDF here.