One of the leading methods of generating renewable energy is through the capturing and use of methane gas obtained from fermentation processes in biogas plants. The digesters used to facilitate this methane production have very specific requirements when it comes to amount and makeup of biomass; too little biomass means less energy and heat generated, therefore revenue lost, but overloading the plant with excessive biomass can have significant negative impacts including the scenario of inactivating the biomass leading to a costly plant restart. Plant operators benefit greatly from having accurate and reliable methods of quantifying biomass and other parameters onsite to assist in optimizing their processes.

Biogas Plant Basics

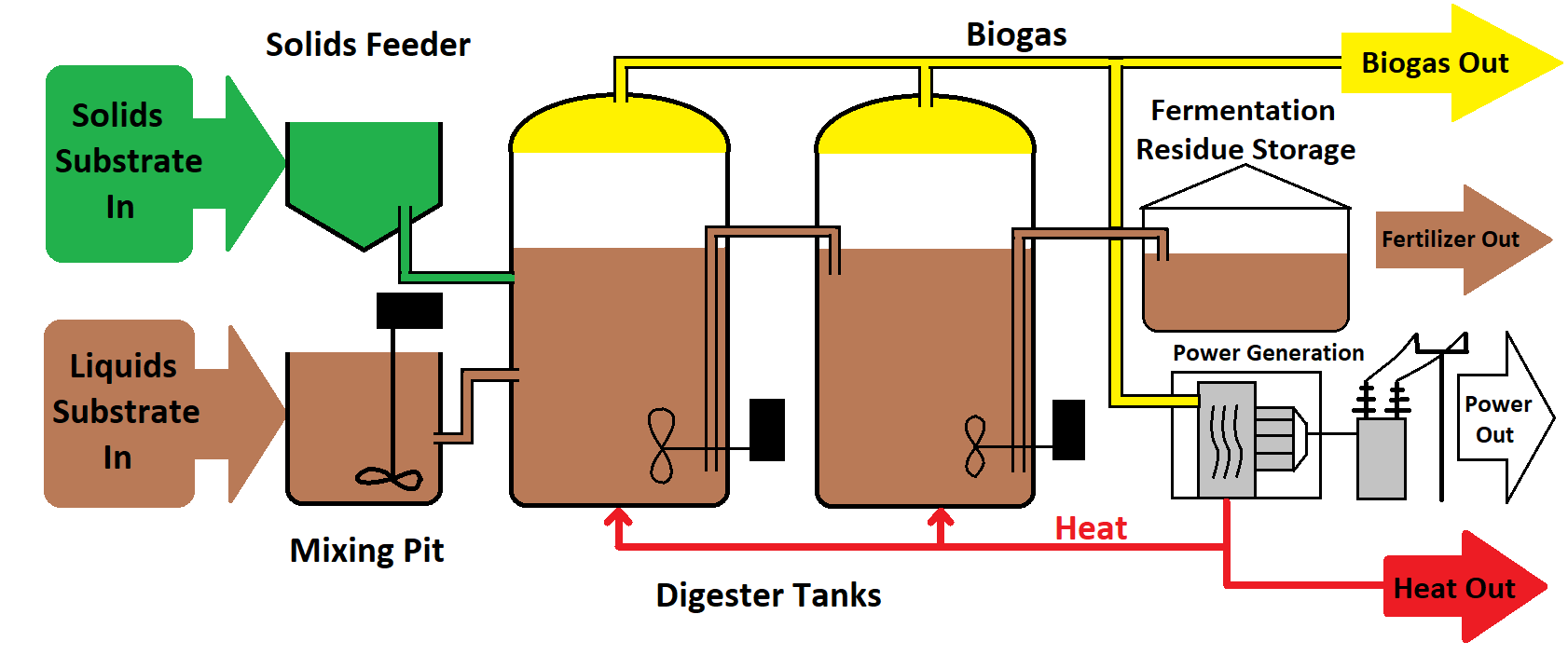

A biogas plant consists of structures hosting different stages of the fermentation processes, with the main aspect being digester tanks hosting a mixture of liquid and solid substrates which act as a home and food for methane-producing bacteria. These digester tanks have multiple biological processes all happening simultaneously, with levels of substrate, temperature, pressure, pH, and other parameters keeping the biological processes optimized for maximum methane production. Below is a diagram of a typical biogas plant:

Optimizing Biogas Production via Process Control

There are a number of chemical and biological parameters that can be measured throughout the plant to optimize conditions for methane-producing bacteria in the digesters. These parameters are detailed below:

Temperature

Methanogenic bacteria are extremely sensitive to temperature fluctuations, so temperature should be controlled to always be within +/- 1 °C. Some biogas plants are mesophilic, and require temperatures between 35 to 41 °C, and other plants are thermophilic and require temperature maintained at a higher 57 °C.

pH

Similar to temperature, methanogenic bacteria prefer a specific pH range. During earlier parts of the process (hydrolysis and acidification) a pH of 4.5 to 6.3 is recommended. For the methane formation stage, pH should be raised to be between 7.0 to 7.7. pH and Temperature should be monitored and adjusted constantly to avoid going outside the ideal range and disrupting biological processes.

Total Solids

Total solids (TS) content must be tightly controlled for the purpose of managing the consistency of solid streams, and also to ensure the digesters are never overloaded. Typical TS content is 8-10% while some digester designs can handle up to 20%.

Redox Potential

The redox potential of the digester provides indication of the oxidisability of the biomass. Biogas production requires an anaerobic environment, and redox potential should be less than 330 mV. Redox should be actively monitored and can be an early indicator of shifts in the biomass activity and also provide early warning before significant shifts in pH.

Acid Capacity (Acidity)

Acid capacity is a measure of the buffering capability of the biomass in the digester. A greater buffering capacity means the biomass will be less susceptible to changes in pH. Acid capacity is measured in mg/L of CaCO3.

COD

Chemical oxygen demand is another method of determining the quantity of oxidisable components in the substrate. This acts as a reliable indicator of the energy potential of the substrate, while also providing early indication of potential plant upsets.

Organic Acids/Fatty Acids

Fatty acids are required for the first and second stage of the fermentation process, and having a measure of these components provides insight to the total potential methane production from a given substrate. These can be determined via the FOS/TAC titration method along with buffering capacity.

Automated Plant Monitoring with MANTECH

MANTECH is happy to provide a wide range of products for quick and easy monitoring of biogas plant parameters, from simple Benchtop configurations (MT5) to fully autonomous Online monitoring systems (MO1000). The PeCOD COD Analyzer provides the fastest method of empirical determination of COD using only green and safe parameters, and MANTECH Pro software allows for user-friendly operation of equipment with quick access “Shortcut buttons” linked to automated methods and detailed instructions. Contact us via our website form or at [email protected] to learn more!