What is SampleProtect?

MANTECH systems are known to produce the quickest analysis times in the market due to its minimal required sample sizes and advanced technology. Nonetheless, conducting analyses on racks with hundreds of positions can raise concerns of degeneration of the sample due to extended periods of air exposure. To ensure the integrity and accuracy of the sample and results, MANTECH has introduced the SampleProtect method. This method covers the top of the sample tubes that are not currently being analyzed by the autosampler. Not only does this method avoid degeneration of sample when exposed to air but some MANTECH customers have also used this method to cover samples due to the odour they produce (e.g., sulfur and ammonia).

What is the SampleProtect Process?

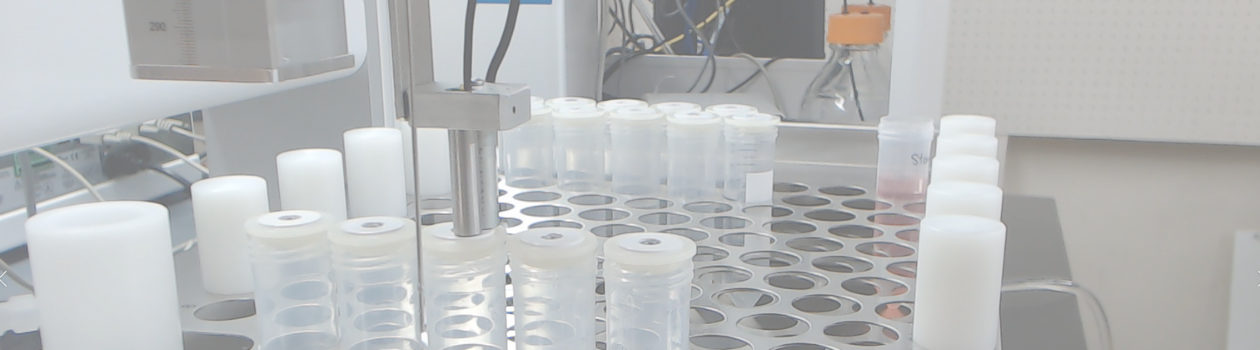

SampleProtect uses a magnet to remove the cap from the top of the sample tube, then to recover the tube when the sample analysis is complete. The use of MANTECH’s smart interface and intelligent software has enabled our team of experts to execute a process that requires such precision. SampleProtect relies on a sensor that is coupled with our smart MiniHub interface and intelligent MANTECH Pro software to compute bi-directional communication. This communication confirms the pick-up and drop off actions of the cover as well as acts as a safeguard for both the probes and needles.

SampleProtect is available on MANTECH’s entire range of autosamplers for our MT10, MT30, and MT100 automated environmental titration systems.

Watch SampleProtect in Action!

Our highly skilled and trained staff would be delighted to provide you with more information about how MANTECH systems can be configured to best suits your laboratory’s needs and requirements. Fill out our convenient contact form here, call us at +1 (519) 763-4245 or email at [email protected]

Visit our YouTube channel for more related videos.