OEC – Oilfield Environmental & Compliance

Case Study on the Impact of the 10-minute Estimator with Automated BOD5 Robotic Analyzer

Click here to download a pdf version of this case study.

The Biochemical oxygen demand (BOD) parameter is a ubiquitous water quality test in North America for pollution control in waste waters and receiving waters (lakes, rivers and sea waters). It is one of the most common parameters on National Pollutant Discharge Elimination System (NPDES) permits and sewer discharge permits. Industrial companies are often invoiced by Utilities on the BOD loading discharged into sewers monthly. The US EPA and Environment Canada regularly monitor Industrial discharges into receiving waters. Environmental compliance fines are often the result of BOD loading infractions from NPDES permit holders. As a result, BOD is a required water quality reporting parameter for Municipal Wastewater Treatment Plants (WWTP) and Industrial plants, with and without on-site wastewater treatment. An accredited environmental laboratory is required to do the BOD testing to ensure accurate results that are unbiased, therefore, they can stand against legal challenges. Environmental regulations are getting stricter, and climate change continues to be an impetus driving this. As a result, the requirement for BOD testing is increasing.

OEC – Oilfield Environmental & Compliance is an accredited environmental laboratory servicing clients in the Central Coast, LA Basin, and San Joaquin Valley. OEC offers laboratory testing services for Environmental, Oil, Gas & Produced Waters, and Field services including Geoprobe drilling. In the Environmental sector, OEC provides testing services for drinking waters, soils, sediments, hazardous waste, and wastewaters. OEC noticed increasing demand in BOD testing and it was decided to investigate the potential to invest in automation versus additional personnel.

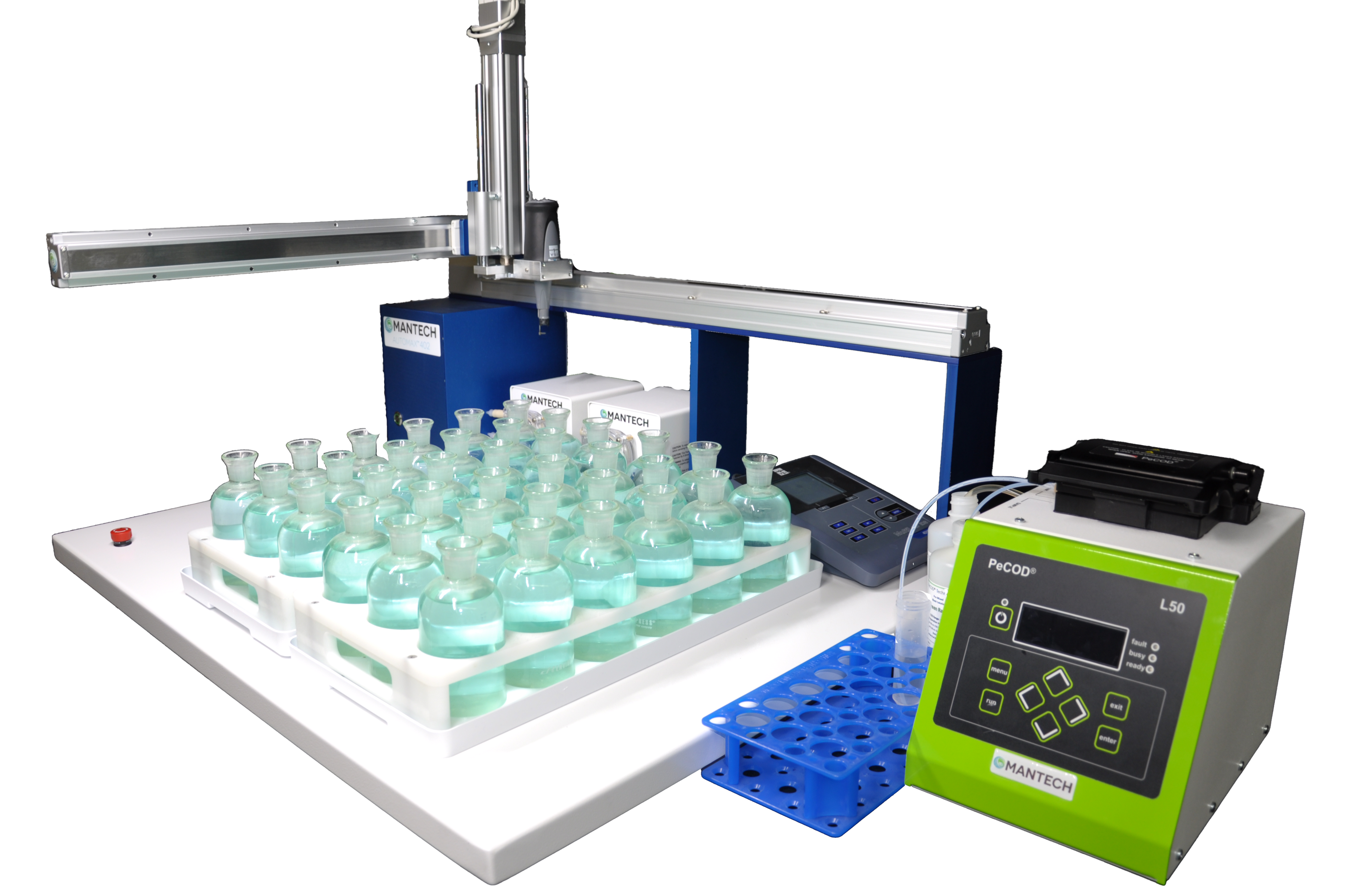

In Q2 of 2020, OEC called MANTECH to enquire about the PC-BOD automated BOD Analyzers. Around the same time MANTECH had recently completed a survey of PeCOD® endusers and learned a surprising fact; approximately 50% of the customers had purchased it as a BOD analyzer versus a chemical oxygen demand (COD) analyzer, for which it had been originally designed. The total end user base was already in the 100’s, therefore, this was significant. PeCOD had proven to provide a reliable BOD5 estimate in 10-minutes, often a stronger correlation than that with the dichromate COD method. MANTECH had then conceptualized the value of the PeCOD as a 10-minute BOD estimator add-on to its automated BOD analyzers. The second phone call after thinking of this, it was still a thought, was OEC. The first was the US Embassy in Baghdad, Iraq (who also invested in the package). It was a good conversation where we discussed the number of bottles to prepare/analyze, expected throughout, how the automated analyzer would work for OEC, etc. Upon completion of this part of the Q&A, MANTECH asked, what percent of your samples do you not know the approximate BOD of? The OEC representative had said it was approximately 10% and in particular winery waster samples were problematic and required many dilutions over a large range to attempt to get a valid BOD result. MANTECH asked, do you think you could benefit from a reliable 10-minute BOD estimator that operates from the same computer at the same time. The answer was yes. MANTECH calls this “Package B” and this is what OEC invested in, namely an automated BOD analyzer with 10-minute BOD estimator package.

- BOD samples demand comes from Municipal Influent and Effluent, Wineries, Breweries and other General Industry.

- Municipal send both influent and effluent. Effluent for compliance and influent to check on treatment performance, for example the degree of BOD reduction from influent to effluent.

- In most cases there is historical data, especially for effluent samples, thus an approximate BOD range is already known.

- The influent can vary, and a visual check on the dirtiness of the sample can indicate an unknown as well.

- In the case of breweries, these can be very high strength, variable and unknown.

- In some cases, 10-15x dilutions were completed to ensure a group of samples were valid and could be averaged.

- In the case of wineries and other industry, there will be cases of little to no historical data, thus the approximate BOD is unknown.

- With the PeCOD, 2 different reliable correlations were determined based on the wastewater matrix.

These are the impacts from utilizing the PeCOD 10-minute BOD result

- OEC is now able to decrease the number of dilutions for unknown samples, for example from 5 to 3. That is 2 less bottles, prepared, measured, incubated and handled!

- OEC narrows the range of the dilutions to improve the accuracy of the BOD results measured and reported.

- OEC saves on materials, water and labor, therefore, saves time and money with a corresponding increase in profit.

MANTECH then asked OEC to comment on the operation and use of the PeCOD. Response is as quoted:

“It was a lot simpler to use than first thought.”

“Actually, really easy to use”

MANTECH appreciates the time OEC gave for this interview.

Definitions:

- PeCOD® is registered trademark owned by MANTECH.

- The core technology is a patented photocatalytic electrochemistry method for oxidizing the organics in real time and measuring the resultant COD.

- The patents related to the peCOD technology are owned by MANTECH.